When it comes to the meat processing industry, precision and innovation are key factors in delivering top-notch products to consumers. Industrial vacuum meat tumblers play a crucial role in enhancing the quality and flavor of meat products, making them a staple in modern processing plants.

In Europe, several manufacturers have distinguished themselves in this field, consistently providing cutting-edge solutions for the meat processing industry. In this blog post, we’ll explore the top 5 industrial vacuum meat tumbler manufacturers in Europe, shedding light on their history, main products, and the innovative technologies that set them apart.

1. FERDINAND HENNEKEN GMBH

Location: Hedderhagen 10, 33181 Bad Wünnenberg – Fürstenberg

Company Type: Manufacturer

Year Founded: 1977

Main Products:

●Tumbler, injector, brine mixer, steaker, flattener, loading systems, cooling and defrosting equipment.

About the Company:

Ferdinand Henneken GmbH is a family owned company that specializes in producing machines for the meat industry. The company is based in Bad Wünnenberg, Germany, where it has a large and modern production facility with a technical center and seminar rooms.

Henneken offers a wide range of machines, such as vacuum tumblers, tenderizers, injectors, brine mixers and flatteners, that are designed to meet the technological and operational needs of the customers. The company prides itself on its high inhouse production depth, its qualified and experienced employees, and its use of quality parts from well-known and internationally operating companies.

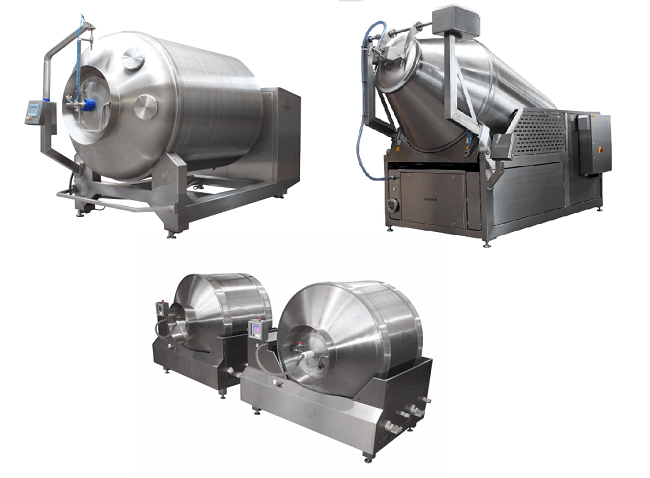

About the Henneken Industrial Vacuum Tumbler:

The Henneken vacuum tumbler type B (upper left) is the company’s bestseller. It can optionally come with a cooling and/or defrosting system, which allows you to process frozen or chilled meat products.

The tumbler and marinator machine has a direct drive that can rotate the drum at a speed of 0.5 to 10 RPM. Operators can easily adjust and program the tumbling parameters, such as vacuum level and tumbling time.

This vacuum meat marinator tumbler can handle various types of meat products, such as boiled ham, smoked ham, kebabs, fish, and poultry. It has a unique feature: the diagonal fins inside the drum. These fins move the meat products in controlled turning, slide and glide movements, creating a three-dimensional mixture effect that activates the protein effectively.

2. Glass Machine

Location: Frankfurter Weg 28 33106, Paderborn

Company Type: Manufacturer

Year Founded: 1972

Main Products:

●Food mixers, food grinder, temperature control machine, emulsifier, flattener, industrial tumblers, industrial fryer, meat tenderizer, cooking machines, cooling blender, vacuum mixer, batch mixer.

About the Company:

GLASS is a top manufacturer and supplier of process plants and special machines for the food industry. They have almost 50 years of experience in the industry, and they are expanding their activities in the production of industrial machines and in the planning of new plants.

The company integrates their company policy with cutting-edge technology, such as 3D-CAD, and ISO 9001 controlled production processes. They ensure a customer-oriented production of all machines, and they have the capability to manufacture a system precisely according to customer-specific requirements and to deliver it within a very short time.

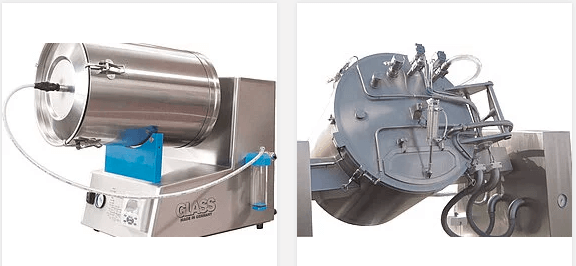

About the Glass Vacuum Meat Tumbler:

The capacity of Glass vacuum tumbler and massaging machines range from 80 to 2700 litres. Their tumbling machines for meat processing have many features, such as automatic lid operation, motorized drum swiveling, adjustable discharge height, scraper, vacuum loader, touch-panel control, different mixing arms, hygienic seals, and industrial cooling system.

Their vacuum tumbler machines can improve the flavor, texture, juiciness, weight, and yield of meat products.

3. Suhner Food Processing Equipment

Location: Fischbacherstrasse 1, 5620 Bremgarten, Switzerland

Company Type: Manufacturer, Distributor

Year Founded: 1939

Main Products:

●Tumblers, injectors, brine mixers, steakers, sausage separators, rotofilters, loaders.

About the Company:

Suhner is a Swiss company that specializes in brine injection technology for the food industry. They have been setting standards in this field since they invented the world’s first brine injector about 50 years ago. The company produces high-quality machines, such as brine injectors, massaging machines, vacuum tumblers and ham presses, that bear their name with pride. The company offer a wide range of machines for the meat and sausage production, as well as for other food products. They are a leading manufacturer and distributor of machinery for meat, poultry and fish processing in Switzerland and beyond.

About the Suhner Vacuum Tumbler:

Suhner VT-Tumbler can perform salting, marinating, tenderising and mixing functions in a vacuum drum that is horizontally positioned for optimal performance. This vacuum tumbler machine is designed to be time and cost efficient, easy to operate and clean, and low in wear and maintenance costs.

This tumbler machine for meat can enhance the flavor and texture, accelerate the curing process and lower the production and storage expenses.

4. Roser Group

Location: Ctra. Riudellots, 11 – 17244 Cassà de la Selva – Girona – Spain

Company Type: Manufacturer

Year Founded: 1959

Main Products:

●Machinery for cured ham, industrial bowl cutters, brine preparation tanks, meat mixers, high pressure brine injectors, continuous vacuum fillers, needle cleaning machine, emulsifier, industrial cooking kettles, sausage peeler, marinated meat brine draining tumbler, meat tenderizer, meat macerator, industrial meat grinders.

About the Company:

ROSER GROUP is a leading company in the design and manufacture of machinery, equipment and facilities for the food industry, with a special focus on the meat industry. Founded in 1959 in Spain by Don Jaime Roser, the company has grown to become a global provider of solutions for the food sector, with subsidiaries and collaborators in more than 50 countries. ROSER GROUP has also invested in innovation and quality, opening a state-of-the-art factory in Mexico in 2008 to serve the North and Central American markets. With an export quota of over 70%, ROSER GROUP is committed to excellence and customer satisfaction in the food industry.

About the Roser Vacuum Tumbler:

The Roser Ogalsa vacuum tumbler for marinating is designed to enhance the flavor and texture of meat products by injecting them with brine under vacuum. This meat marinade tumbler machines have a user-friendly HMI integrated system that allows the operator to choose from different maceration programs and monitor the process. It also has a helical paddle system that gently massages the meat without damaging it, ensuring a uniform and optimal absorption of the brine.

This vacuum tumbler for meat processing is suitable for different types of meat products, such as poultry, pork, beef, and fish, and can improve their quality, yield, and shelf life.

5. Taibo Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Meat bowl chopper, stuffing fillings mixing machine, meat grinder, frozen meat block flaker, frozen meat dicing equipment, vacuum meat marinade tumbler, equipment for meat processing products.

About the Company:

Taibo Machine emerges as a prominent player in the world of industrial vacuum tumbler machine despite its roots in China. Renowned for its cutting-edge technology and commitment to excellence, Taibo Machine has earned its place among the top manufacturers globally, including Europe.

While their roots may trace back to China, Taibo Machine has successfully transcended borders to become a key player in the European market. Their commitment to quality, advanced engineering, and customer satisfaction has resonated with businesses across Europe, making them a trusted choice for industrial vacuum meat tumblers.

Taibo Machine takes pride in its ability to provide innovative solutions that cater to the specific needs of the European market. Their state-of-the-art industrial vacuum meat tumblers and other food processing machines have found favor among European manufacturers for their efficiency, reliability, and ability to meet stringent industry standards.

About the Taibo Vacuum Meat Tumbler:

This company manufactures a range of vacuum meat tumbler machines that can handle both frozen and fresh meat, with capacities from 100 to 5000 liters. Their meat processing machines are designed for dicing, grinding, chopping, slicing, mixing, marinating and emulsifying, producing high quality cuts with little waste. Taibo Machine’s vacuum meat tumbler machines are more affordable and efficient than those of some European manufacturers.

Conclusion

In conclusion, the European landscape boasts a diverse array of industrial vacuum meat tumbler manufacturers, each contributing to the evolution of the meat processing industry.

As consumer demands for high-quality and diverse meat products continue to rise, these manufacturers stand at the forefront, innovating and delivering solutions that shape the future of the industry. Whether you are in search of advanced tumblers, injectors, brine mixers, or other processing equipment, the companies mentioned in this blog post are undoubtedly leaders in the field, embodying excellence in industrial vacuum meat tumbling technology.

More to Read

●Best 5 Industrial Vacuum Meat Tumbler Manufacturers in Poland

●Top 4 Industrial Vacuum Meat Tumbler Manufacturers in Canada

●Best 6 Industrial Vacuum Meat Tumbler Manufacturers in US