Introduction

In the world of food processing, consistency and quality are key. Industrial automatic frying machines are essential for businesses looking to produce high-quality fried foods are scale. These machines offer precision, speed, and cost-effectiveness, making them a staple in many production lines.

Whether you’re in the snack industry or operating a large-scale fast-food chain, understanding how to choose and maintain an industrial fryer can significantly impact your business.

Ⅰ. Types of Industrial Frying Machines

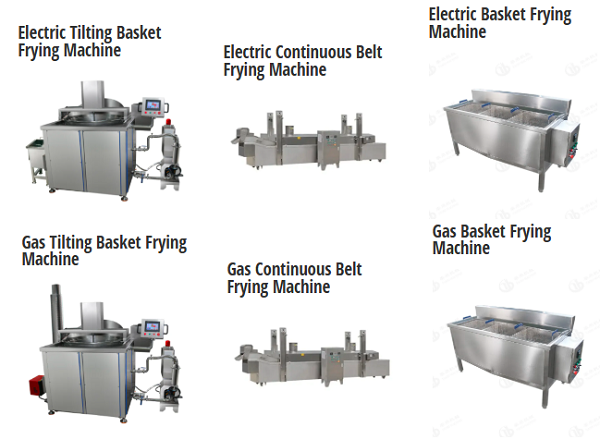

Industrial frying machines can be categorized in two main ways: by frying method (batch vs. continuous) and by energy source (gas vs. electric). Here’s a breakdown of each category:

By Frying Method:

●Batch Fryers

Batch frying machines are ideal for smaller production runs or businesses with less frequent frying needs. They cook a set amount of food at once and always come with baskets.

These machines allow for flexibility and are typically used in artisanal food production or foodservice establishments where different food items need to be fried in small batches.

●Continuous Fryers

Continuous frying machines are best suited for high-volume operations. They are designed to fry food as it moves through the system without interruption.

This method ensures uniform frying and maximizes production efficiency, making continuous fryers the go-to choice for large-scale snack production or fast-food chains that need to produce large quantities quickly.

By Energy Source:

●Gas Frying Machines

Gas type frying machines use natural gas or propane to heat the oil, offering quick heat-up times and high cooking efficiency. Gas fryers are known for providing consistent, even heat, which is ideal for operations that require high-capacity frying. Gas-powered fryers tend to be more energy-efficient in certain production settings, especially where gas is readily available and more economical than electricity.

●Electric Frying Machines

Powered by electricity, electric frying machines are known for their precise temperature control and energy efficiency. These fryers are a popular choice for smaller to medium-sized operations or businesses located in areas where electricity is more accessible than gas. Electric fryers are typically easier to maintain and offer a more straightforward setup compared to gas fryers.

Ⅱ. Key Features of Quality Frying Machines

A good industrial frying machine for fish and chips, burger, chicken, and French fries is more than just a tool for cooking food. It’s a system that ensures your products come out perfect every time, with features that maximize efficiency and reduce operational costs. Here are 3 key features that set high-quality fryers apart:

1. Precise Temperature Control

Maintaining a consistent frying temperature is crucial to ensure even cooking. Quality frying machines for restaurants are equipped with advanced temperature control systems that allow for fine adjustments, helping to produce the perfect crisp every time.

2. Oil Filtration Systems

Oil quality directly impacts the flavor and texture of fried foods including doughnut, cashew nut, onion groundnuts and so on.

Fryers with built-in oil filtration systems help extend the life of the oil by removing food particles and impurities. This not only improves the quality of fried products but also reduces the need for frequent oil replacement, cutting down on operational costs.

3. Energy Efficiency

Industrial frying machines and commercial frying machines consume a significant amount of energy. Modern fryers are designed to optimize energy use, incorporating energy-saving technologies such as insulated fryers and advanced heating elements to reduce electricity consumption and lower energy costs.

Ⅲ. Benefits of Using Industrial Frying Machines

Investing in high-quality industrial frying machines offers numerous benefits for businesses. Here are 4 reasons why they’re a game-changer for the food industry:

1. Increased Production Speed

With their ability to fry large quantities of garri, chicken, fries and other foods quickly, heavy duty frying machines significantly boost production speed. Whether you’re making potato chips, chicken nuggets, or French fries, a good fryer helps you meet high demand efficiently.

2. Consistent Results

One of the biggest challenges in food production is maintaining consistency. Frying machine equipment ensures that each batch of food is fried to the same standard, with the same texture, flavor, and appearance. This level of consistency is crucial for businesses looking to maintain product quality and customer satisfaction.

3. Improved Food Safety

Many industrial frying machines come with features designed to enhance food safety, such as automated oil filtering systems that maintain oil quality and prevent contaminants. Additionally, precise temperature control reduces the risk of overcooking or undercooking food, ensuring that every batch is safe to eat.

4. Healthier Fried Foods

With the growing demand for healthier options, many industrial fryers now come with low-oil absorption technology, helping to reduce the amount of oil absorbed into fried products. This results in healthier, lower-calorie foods without compromising on taste.

Ⅳ. Frying Machine Cleaning, Maintenance and Longevity

A well-maintained frying machine can serve your business for years, offering reliable performance and high production output. Here are 3 tips to ensure your industrial frying machine remains in top condition:

1. Regular Cleaning

After each use, clean the fryer to remove food residue, oil, and debris. Regular cleaning helps to prevent build-up and keeps the fryer running smoothly.

2. Oil Replacement

Depending on the frequency of use, you should replace the oil regularly. Many fryers come with oil filtration systems that help extend the life of the oil, but it’s still important to check oil quality frequently.

3. Check for Wear and Tear

Keep an eye out for signs of wear on parts like heating elements, filters, and belts. Regular maintenance checks can help you catch potential issues before they become major problems, extending the life of your equipment.

Ⅴ. Why Choose Our Industrial Frying Machines?

At Taibo Machine, we specialize in manufacturing high-quality industrial frying machines designed to meet the unique needs of your business. Whether you’re looking for a basket batch frying machine for small-batch production or a continuous large frying machine for high-volume output, we have a solution that’s right for you.

(Click to know more.)

Our food fryers come equipped with advanced features like precise temperature control, energy-efficient designs, and reliable oil filtration systems, ensuring that your production is fast, efficient, and cost-effective.

Plus, our machines are built to last, with durable materials and easy-to-maintain designs.

Ⅵ. Ready to Upgrade Your Production?

If you’re ready to take your food production to the next level, contact us today to learn more about our industrial frying machines. We’re here to help you choose the perfect fryer for your business and ensure you’re getting the most out of your equipment.

More to Read

●Best 5 Industrial Frying Machine Manufacturers in the United States

●Comprehensive Guide to Beetroot Equipment: Washing, Peeling, Dicing and Slicing Solutions

●A Comparative Look at Leading Vegetable Peeling Machine Manufacturers

●The Definitive Guide to Vegetable Peeling Machines

●Slice and Dice Excellence: Discover the World’s Top 7 Food Cutting Equipment Manufacturers

一个回复