Introduction

Fruit grading equipment plays a vital role in today’s fresh produce industry. As demand for efficiency and precision grows, manufacturers of fruit grading equipment continue to innovate with advanced technology that helps growers and packers streamline operations.

Australia is home to some of the world’s leading fruit grading equipment manufacturers. In this blog, we’ll introduce four prominent companies—Taibo Machine, GP Graders, KW Automation, and Wyma Solutions—highlighting their history, product innovations, and key grading machines designed to meet the needs of growers and packers across the globe.

1. GP Graders

Location: 8-12 Gilby Road, Mount Waverley, Victoria, 3149 Australia

Company Type: Manufacturer

Year Founded: 1963

Main Products:

●Cherry sorting technology, blueberry sorting technology, snack tomato sorting technology, nectarine sorting technology, stone fruit sorting technology, oyster sorting technology, sanitary machines.

About the Company:

GP Graders is a multi-award-winning global leader in vision sorting and grading technology, serving the fresh produce industry since 1963. With over six decades of expertise, the company has built a strong reputation for delivering innovative, reliable, and specialized machinery solutions to fresh produce packers worldwide.

At the core of GP Graders’ success are five guiding pillars: leadership through innovation, small fresh produce grading expertise, customized designs, local support, and uncompromising quality manufacturing. Recognized as an industry specialist in small produce such as cherries, blueberries, cherry and grape tomatoes, and tree fruit, GP Graders provides tailor-made solutions that align with each client’s production volumes, facility layouts, and long-term growth plans.

For fresh produce businesses seeking advanced technology, durability, and trusted global support, GP Graders continues to set the benchmark for grading and packing excellence worldwide.

About the GP Graders Nectarine Sorting Machine:

Built on decades of proven expertise, the nectarine sorting machine from GP Graders sets a new benchmark in accuracy, reliability, and ease of use. Leveraging more than 30 years of nectarine grading experience and supported by hundreds of installations worldwide, this solution combines advanced weight grading with intelligent software to deliver unmatched performance in packhouse operations.

The redesigned gp601 grading platform ensures maximum productivity, with a 3-lane configuration capable of processing over 2 tonnes per hour. This efficiency not only accelerates packhouse output but also helps generate a faster return on investment. Operators benefit from precision size separation, guaranteeing consistent results—for example, a 67mm nectarine always reaches the correct lane for premium-grade packaging.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Centrifugal deoiling machine, produce washing equipment, vegetable dryer machine, vegetable grading equipment, fruit grading equipment, dough rounder machines, carrot cutter machine, beet slicer, mango washing machine.

About the Company:

Taibo Machine is a leading manufacturer specializing in the design, production, and supply of advanced food processing machinery.

Their product range covers a wide spectrum of equipment, including meat processing machines, vegetable and fruit processing machines, dough processing equipment, nuts processing machines, frying machines and dehydrating drying machines. Each machine is built with high-quality stainless steel and advanced technology to ensure safety, hygiene, and long-lasting performance in demanding production environments.

With a growing international presence, Taibo Machine is committed to helping businesses around the world streamline operations, expand production capacity, and achieve success with trusted, built-to-last machinery.

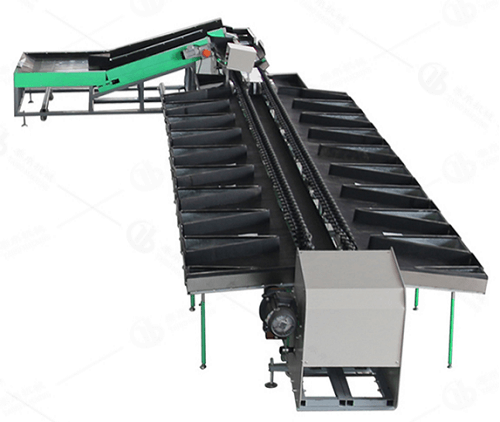

About the Vegetable Fruit Weight Grading Equipment:

This vegetable fruit weight grading equipment is designed to deliver fast, precise, and reliable sorting for a wide range of produce. Using advanced electronic weighing technology, it automatically grades fruits and vegetables by weight, ensuring uniform product quality and consistency for packers and processors.

Capable of handling diverse products such as apples, avocados, lemons, limes, citrus, tomatoes, potatoes, onions, and more, the machine offers high throughput with minimal labor input. Its customizable grading settings and user-friendly interface allow operators to easily adjust size ranges to meet market and customer requirements.

(More to Read)

By combining accuracy, speed, and robust design, Taibo’s vegetable weight grader machine helps businesses reduce waste, enhance product presentation, and maximize profitability.

3. KW Automation

Location: Old Bowling Green Road, Palmwoods, Queensland, Australia

Company Type: Manufacturer

Year Founded: 1970s

Vegetables and Fruits:

●Avocado, mangoes, citrus, apple, stone fruit, pear, tomatoes, passion fruit, lychee, watermelon, rock melon, kiwi fruit, custard apple, squash, pumpkin, capsicum, ginger, onion, oyster, abalone.

Main Products:

●Bulk bin tipper, brush wash or wax unit, drying tunnel, polish units, inspection conveyor, electronic weight sizer, circular weight grader, inline weight grader, diverging belt grader, wash tank, pressure wash, ginger washer.

About the Company:

KW Automation is a family-owned, 100% Australian company with a proud history of innovation in horticultural and aquaculture automation. It pioneered solutions such as circular fruit weight grading machines, setting new standards for accuracy and efficiency.

The company designs and manufactures a wide range of advanced equipment, including graders, washers, conveyors, and specialized peripheral machinery. All products are built at the company’s facility in Palmwoods, Queensland, with a focus on quality, reliability, and affordability.

From mechanical systems to state-of-the-art electronic weight graders capable of handling nearly all fruit types with exceptional precision, KW Automation’s technology evolves to meet the industry’s changing demands.

About the KW Automation Electronic Weight Sizer for Avocado:

KW Automation’s inline electronic weight sizer helps growers and packers deliver perfectly presented produce that commands higher market value. Utilizing advanced technology, the system captures up to 100 simultaneous weight readings per piece, ensuring unmatched precision across a wide range of fruit types—from delicate plums to large mangoes.

Designed for flexibility, the sizers feature pre-programmed weight settings accessible via a simple keyboard interface, allowing operators to quickly adapt to changing packing requirements. With the ability to process up to 15,000 pieces of fruit per lane per hour, and scalable configurations of up to 8 lanes, the system is ideal for both medium and large-scale operations.

Built to rigorous quality standards, this weight sizer machine for various vegetables and fruits can function as a standalone unit or be seamlessly integrated into a complete KW Automation processing line.

4. Wyma Solutions

Location: U3/15 Priority Court, Edinburgh North, South Australia 5113, Australia

Company Type: Manufacturer

Year Founded: 1962

Main Products:

●Bin fillers, vegetable polisher, barrel washer, combi-washer, flat bed brusher, pumpkin brusher, vegetable trimmer, vegetable peeler, lift roller sizer, screen sizer, vibrating length sizer.

About the Company:

Wyma Solutions is a global leader in post-harvest vegetable and fruit handling equipment, trusted by growers and packers for over 50 years.

Since its establishment, Wyma has built a reputation for delivering high-quality, innovative, and reliable solutions tailored to customer needs. From washing and polishing to grading, conveying, and complete turnkey systems, Wyma equipment helps businesses reduce waste, maximize efficiency, and achieve the best possible presentation and value for their produce.

At the heart of Wyma’s approach is collaboration. The company works closely with customers to design solutions that reflect their unique conditions, scale of operation, and produce varieties.

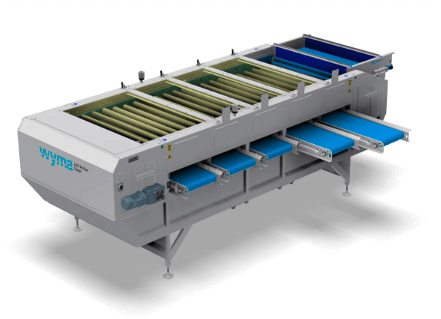

About the Wyma Lift Roller Sizer:

The Wyma lift roller sizer is a versatile and reliable diameter grader designed to handle a wide variety of fruits and vegetables, including carrots, potatoes, parsnips, beets, citrus, onions, bulbs, Brussels sprouts, and rutabaga. Engineered for flexibility, it provides multiple size outputs at high capacity in a single machine, making it an ideal solution for growers and packers with diverse product requirements.

Using adjustable roller spacing, this lift roller sizer creates defined size bands that deliver consistent and accurate grading. Its innovative design ensures produce is gently rotated during sizing for improved uniformity. As the rollers advance, the top rollers lift on a series of ramps to create openings where produce drops through to dedicated cross conveyors, which then carry it to the next stage in the line. Adjustments to ramp heights can be made electronically or manually—even while the machine is in operation—providing seamless control and flexibility.

Conclusion

From Taibo Machine to Wyma Solutions, these manufacturers are shaping the future of fruit grading with equipment built for accuracy, efficiency, and reliability. Whether you’re handling small fruits like cherries and blueberries or larger produce like avocados, mangoes, and root vegetables, choosing the right grading equipment can make all the difference to your productivity and profitability.

Considering investing in fruit grading equipment? Explore the solutions offered by these trusted manufacturers to find the perfect fit for your operation.

More to Read

●Best 4 Fruit Grading Equipment Manufacturers in Italy

●Top 4 Beet Peeling Machine Manufacturers in India

●Everything You Need to Know About Centrifugal Deoiling Machines

●Best 5 Industrial Lettuce Washing Equipment Manufacturers Around the World

一个回复