Vegetable Peeling Machine

Efficient, stable, and hygienic peeling solution for vegetables

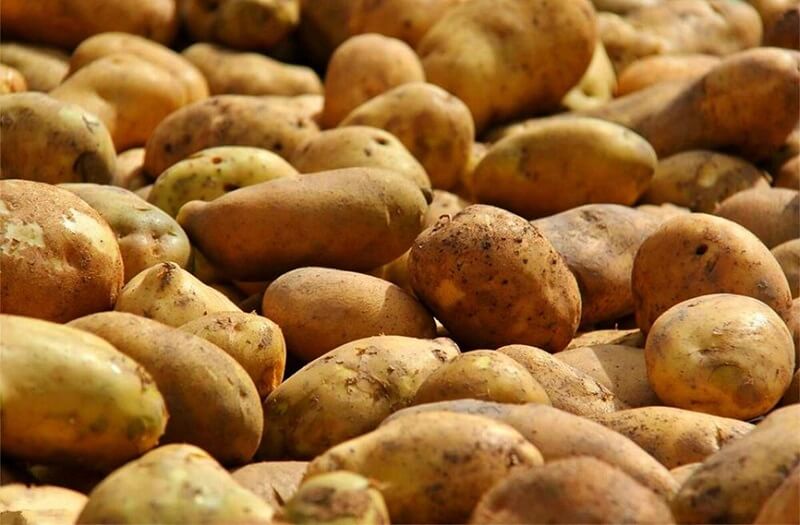

- Suitable for potato, carrot, ginger, sweet potato, radish, taro, cassava, beetroot and other root vegetables

- Adjustable peeling depth for different raw materials

- SUS304 stainless steel construction

Who Is This Machine For

If you are looking for a reliable peeling machine for continuous operation, this model is designed for your needs.

Vegetable Processing Factories

Frozen Vegetable and IQF Plants

Central Kitchens and Food Preparation Centers

What Vegetables Can Be Processed?

Different brush roller and emery roller configurations can be selected according to vegetable hardness and skin thickness.

Potato

Carrot

Sweet Potato

Cassava

Taro

Beetroot

Not sure if your root vegetable is suitable?

How Does the Vegetable Peeling Machine Work?

The vegetable peeling machine for carrot, potato, cassava and other root vegetables uses brush roller peeling and high pressure spraying technology, ensuring stable output, uniform peeling, and easy operation.

Washing & Peeling with Raw Material Loaded

Through rotating brush rollers and high pressure water spraying, dirt, sand, and outer skins are removed simultaneously, ensuring efficient cleaning and uniform peeling.

Clean Product Discharge

After washing and peeling, the clean vegetables are smoothly discharged from the outlet.

The processed material is ready for cutting, further processing, or packaging, with minimal surface damage.

Waste & Wastewater Discharge

Peels, residues, and wastewater are discharged separately through the waste outlet.

This design keeps the processing area clean and supports continuous, hygienic operation.

Key Engineering Highlights

Heavy-Duty Stainless Steel Construction

The carrot potato peeling machine features 6 mm thick SUS304 stainless steel side plates, shafts, bearings, and housings, ensuring excellent corrosion resistance, easy cleaning, and a long service life.

Stable & Efficient Peeling Performance

Durable PBT brush rollers and abrasive rollers provide consistent washing and peeling results, while the optimized discharge outlet ensures smooth and complete material output.

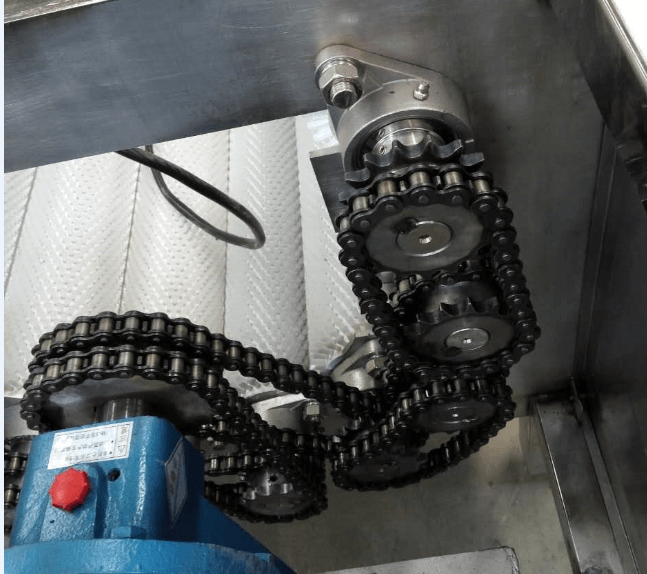

Reliable Drive System for Wet Environments

A gear and chain transmission system prevents slipping under humid conditions, offering more stable and reliable operation compared to belt-driven designs.

Customer Feedback & Application Videos

Real applications of vegetable peeling and washing machine in different markets processing different materials.

Pakistan-Potato Peeling Washing Application

Potatoes with soil are continuously washed and peeled using our root vegetable peeling machine.

The machine ensures stable performance for potato processing under local operating conditions.

Ecuador-Cassava Peeling Application

Fresh cassava is washed and peeled efficiently to remove soil and outer skin.

This application demonstrates the machine’s adaptability to different root vegetables and processing environments.

Processing results may vary depending on raw material condition and capacity requirements.

We recommend selecting the suitable configuration based on your vegetables and production needs.

Recommended Equipment Combination

Build an efficient vegetable processing line with compatible equipment

Common Buyer Questions

Peeling loss depends on vegetable type and peeling depth. The machine allows adjustment to balance appearance and yield.

Yes. Capacity, voltage, brush type, and machine size can be customized according to your requirements.

The machine is designed for easy access and cleaning, suitable for food processing environments.

We provide export packing, technical support, and after-sales service for overseas customers.

Get the Right Vegetable Peeling Solution for Your Processing Needs

Tell us your vegetables, capacity, and processing requirements.

Our engineers will recommend the suitable machine configuration for you.