Introduction

The Netherlands is globally recognised for its advanced agricultural and food processing technology. From washing and sorting to cutting, dicing, and grading, carrot processing machines made in the Netherlands play a vital role in improving efficiency and ensuring consistent product quality.

In this article, we highlight four well-known carrot processing machine manufacturers: Taibo Food Machine, ZTI Machines & Robotics, Marcelissen Food Processing Machinery, and Jegerings.com Special Food Machinery. These companies provide a wide range of solutions for carrot processing, including carrot cutters, belt slicers, long product cutters, sorting machines, and complete vegetable processing lines.

Whether you are looking for a single carrot cutting machine or a complete carrot processing line, this guide will help you understand each manufacturer, enabling you to make a more informed decision for your processing needs.

1. ZTI Machines & Robotics

Location: De Dijken 1, Tuitjenhorn (The Netherlands)

Company Type: Manufacturer

Year Founded: 1989

Main Products:

●Mango peeler, radish top and tailer, bell pepper line, long product cutter, cabbage corer, fruit cutter citrus, dicer.

About the Company:

ZTI Machines & Robotics is a specialist in designing and building smart, high-quality machines for processing fruits, vegetables, flowers, seeds, and other fragile products. As a small and dedicated organisation, the company strongly believes in personal attention. They work closely with every customer, ensuring accessibility, clear communication, and a high level of commitment from the first idea to the final solution.

Their strength lies in delivering tailor-made solutions. They do not believe in standard machines when a better result can be achieved through innovation. By thinking beyond traditional methods, they develop reliable, efficient, and future-proof machines that truly meet your production needs.

Through smart industrial innovations, the company reduces manual and repetitive work, making production processes lighter, safer, and more efficient. At the same time, they focus on sustainable use of raw materials by maximising yield and minimising waste.

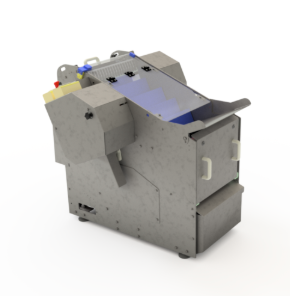

About the ZTI Long Product Cutter:

The long product cutter is designed for the efficient processing of long vegetables such as carrots, parsnips, and cucumbers. It automatically removes the head and butt of each product and then cuts it into evenly sized pieces with high precision and consistency.

Thanks to the integrated stepper system, each product is correctly oriented and separated, ensuring that only one piece is processed at a time. This guarantees accurate cutting and prevents product damage. In the final cutting stage, the product is sliced into equal pieces with a minimum length of 25 mm or multiples thereof.

Built for durability and hygiene, this carrot cutter features stainless steel motors and a stainless steel electrical cabinet. With a capacity of up to 75 products per minute, it delivers high throughput while maintaining gentle product handling, maximum yield, and an attractive end result.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Batch fryer, meat processing equipment, vegetable grading equipment, vegetable washing machine, carrot cutter machine, beetroot cutter, industrial meat mincer, frozen block grinder.

About the Company:

Taibo Machine is a professional manufacturer and supplier of food processing machinery. With years of manufacturing experience, Taibo Machine serves customers worldwide, providing both individual machines and complete production lines tailored to different processing needs.

The company’s product range covers a wide variety of food processing equipment, including machines for vegetable processing, potato chips and French fries production, meat processing, dough and bakery processing, frying, washing, cutting, peeling, seasoning, drying, and packaging preparation. All machines are designed to improve productivity, reduce labour costs, and ensure stable, consistent product quality.

About the Taibo Carrot Dicer:

The vegetable dicing machine reliably cuts a wide range of root vegetables into uniform cubes or sticks by removing the cube blades. It is suitable for potatoes, carrots, cassavas, beetroot, onion and sweet potatoes.

Its robust cutting system uses a three-stage blade assembly that slices, strips, and then dices vegetables into precise cube sizes — from small dices up to larger cubed formats — all in one easy process. Standard cube sizes include 5×5×5 mm and 10×10×10 mm, with other sizes available on request.

Simple operation and a compact design make the carrot dicer easy to integrate into existing production lines or use as a stand-alone unit, which makes it ideal for food processing factories, restaurants, and fresh-cut produce facilities seeking efficient, consistent results.

Whether you’re producing diced vegetables for frozen food lines, dehydrated products, pickles, or ready-to-cook assortments, this industrial vegetable dicing machine offers reliable performance, hygienic design, and consistent quality you can depend on.

3. Marcelissen Food Processing Machinery

Location: Blauwwater 14, 5951 DB Venlo

Company Type: Manufacturer

Year Founded: 1949

Main Products:

●Automatic destoner, washing drum, roller brushing machine, drum roller peeler, batch knife peeler, optical sorter, segmenting machine, continuous halving machine, top/tail and plug cutting machine, split sorter, potato diameter sorter, roller sorting machine.

About the Company:

Marcelissen is a trusted supplier of high-quality food processing machines, specialised in solutions for peeling, inspecting, cutting, sorting, and transporting potatoes, root vegetables, fruits, and nuts. With a strong focus on innovation, quality, and reliability, Marcelissen supports food processors worldwide in achieving the best possible product results.

With more than 75 years of experience, Marcelissen has developed a deep understanding of both the market and customer needs. Every project is unique and approached with personal attention. By working closely with customers, Marcelissen ensures that the right machine is engineered and delivered for each specific process.

Marcelissen works side by side with customers, visiting production sites to fully understand their challenges and ambitions. This close collaboration ensures tailored solutions that deliver the best quality results.

About the Marcelissen Roller Sorting Machine:

This roller sorting machine is designed for accurate sorting of root vegetables and fruits by diameter. It is ideal for products such as sweet potatoes, carrots, celeriac, and beets, delivering consistent and reliable results even in high-capacity production environments.

The vegetable sizing machine uses rotating sorting rollers that are transported between two parallel chains, allowing products to be sorted gently and efficiently. Sorting sizes are stepless adjustable from 9 to 90 mm, giving you full flexibility to match different product requirements. The transport speed can also be easily adjusted using a frequency controller, ensuring optimal control of the sorting process.

To improve working conditions, the machine is equipped with noise-damping rollers, significantly reducing operational noise. A flexible sorting opening enhances performance, while the central lubrication system simplifies maintenance and extends machine lifespan.

4. Jegerings.com Special Food Machinery

Location: Stationsstraat 130, 5751 HJ, Deurne, The Netherlands

Company Type: Manufacturer

Year Founded: 1939

Main Products:

●Vegetable belt cutting machine, vegetable dicing machine, vegetable press, vegetable washing machine, centrifugal vegetable drying machine, potato peeling machine, vegetable processing line.

About the Company:

Jegerings.com specialises in designing and manufacturing high-quality machinery for the vegetable processing industry. Their mission is to provide effective, user-friendly, reliable, safe, and durable machines that support vegetable processors worldwide.

The company offer a comprehensive range of machinery for peeling, cutting, washing, and drying all types of vegetables. Designed specifically for fresh vegetable processing companies, their machines deliver consistent performance, flexibility, and high product quality. Each solution is engineered to handle a wide variety of vegetables, making their equipment suitable for many processing requirements.

Their product portfolio includes vegetable peeling machines for root vegetables such as potatoes, sweet potatoes, beetroots, and yams; high-precision cutting machines for slicing, dicing, and shredding; washing systems that thoroughly remove dirt and contaminants; and centrifugal drying machines that efficiently remove excess water and extend shelf life.

About the Jegerings Carrot Belt Slicer:

The vegetable belt slicer combines high capacity with outstanding cutting precision, making it an ideal solution for professional vegetable processing companies. Designed to handle almost all types of vegetables, leafy greens, salads, herbs, and fruits, the vegetable cutting machine delivers consistent, high-quality cutting results at capacities of up to 1,000 kg per hour.

Thanks to its advanced rotating knife system with stainless steel rollers and ultra-sharp blades, the machine ensures clean, uniform cuts across a wide range of products, including cabbage, onions, peppers, carrots, cucumbers, potatoes, tomatoes, and lettuce. A wide selection of cutting discs allows for slicing, dicing, shredding, julienne cutting, grating, and more, providing maximum flexibility for different production needs.

Cutting sizes and machine settings can be adjusted with just a few touches, while operating hours are clearly displayed to support efficient maintenance planning.

Conclusion

When selecting a carrot processing machine supplier, it is important to consider factors such as processing capacity, machine durability, ease of cleaning, level of automation, and after-sales service. The manufacturers featured in this article offer a wide range of solutions to suit both small processors and large-scale industrial operations.

Looking for the right carrot processing machine for your production line? Contact Taibo today to help you increase efficiency, improve product consistency, and grow your carrot processing business with confidence.

More to Read

●Unlocking Efficiency in the Factory: A Guide to Carrot Processing Equipment

●The Ultimate Guide to Industrial Carrot Washing Equipment

●Efficiency Unleashed: Industrial Carrot Cutting Machine Demystified