About Taibo

Taibo is a professional manufacturer of food processing machines and customized processing lines.

We serve food producers, distributors, and engineering partners worldwide.

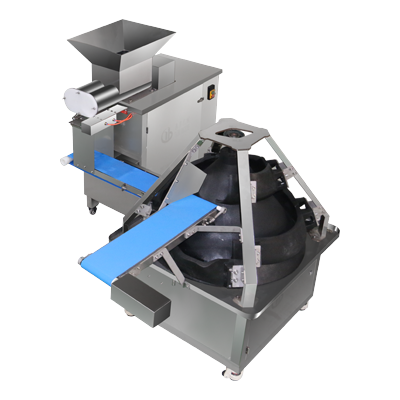

Divide All Kinds of Dough Just by One Machine-The Ultimate Solution

Combination of dough divider and dough rounder allows you to produce perfect dough balls consistently and efficiently. With this production line, all your chapati, roti, pitta bread look and taste great.

The dough divider rounder is a line consisting of MF3 dough dividing machine and MR3 dough rounding machine, which combines the advantages of both machines

Dough divider makes portioning bulk dough easier. It is an absolute necessity for pizzerias, bakeries, tortilla factory and other businesses that require perfectly-portioned dough pieces.

Dough divider is applicable not only to dough but also to date paste, sweet bean paste, cheese, etc.

Conical dough rounder is applicable to both medium and sticky dough pieces in a wide range of weights. Perfectly rounded dough balls work better in the following processes like moulding and pressing

Doubt whether our dough divider is applicable to your dough? Provide us with your recipe or materials and we’ll test the machine with it for free. We strive ceaselessly to improve every kind of bakery product.

Step1. Prepare raw materials as to your recipe.

Step2. Test how the equipment performs with the dough.

Step3. Evaluate how well the the machine works and whether further improvements and adjustments are needed.

Step4. Schedule a video meeting or send videos to show you the machine test. After making sure the machine fits your requirements perfectly, we’ll package and ship it.

We take care of every trifle, including selecting raw material, manufacturing, packaging, logistics, etc. All you have to do is sit back and relax.

Since the factory was founded nearly a decade ago, we’ve been manufacturing the food processing machines on the idea that fine engineering and scrupulous manufacturing leads to high-quality and long-lasting products.

We go all out for food safety and equipment quality. Food grade SUS304 stainless steel, teflon coating, food grade pvc and branded electrical components are our guarantee of extraordinariness.

Before packaging, we’ll check whether the machine works well and whether the accessories are complete. Our customers know that behind every product delivery is a promise of reliable customer service.

Professional factory, comprehensive supply chain and transit system contribute to our ability to manufacture and deliver in bulk, setting us apart from thousands of dough processing equipment suppliers.

All the money you paid to Taibo for purchasing products is secure. Below is an outline of how we turn the payment into equipment.

After all the details such as specifications and voltage of the equipment are set, we will collect the deposit and then arrange the production.

We’ll issue the production task order to the factory after receiving the deposit.

Production tasks will be assigned to each production team. In the meantime, the production team will purchase raw materials and components from suppliers.

Process raw materials into required specification by machining and sheet-metal working.

Engineers assemble all components together ad test the machine.

Show customers the finished equipment by videos or pictures. Improve or adjust the equipment if necessary.

If the machine is built to the complete satisfaction of the customer, we’ll collect the final payment.

After the final inspection, we’ll package the equipment up and load it onto the truck.

Taibo is a professional manufacturer of food processing machines and customized processing lines.

We serve food producers, distributors, and engineering partners worldwide.