Introduction

In the dynamic world of food processing, frying machines play a crucial role in delivering the crispy, delicious products consumers love. From potato chips to seafood, these machines are essential for achieving consistent quality and efficiency in production.

This blog will explore some of the leading frying machine manufacturers in UK., highlighting their expertise, innovative solutions, and contributions to the industry.

1. FLO-MECH

Location: Flo-Mech House, Paxton Road, Orton Goldhay, Peterborough, PE2 5YA, UK

Company Type: Manufacturer

Year Founded: 1974

Main Products:

●Potato destoning, dewooding and wash system, potato peeling equipment, potato grading machinery, potato slicing equipment, potato chips and crisps frying system, box tipping systems.

About the Company:

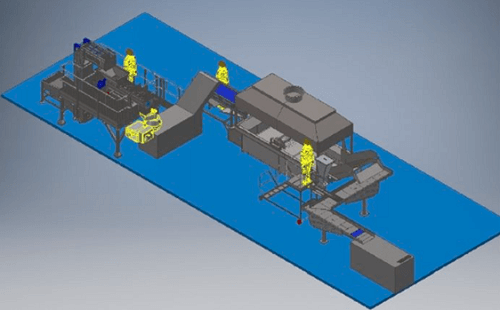

Flo-Mech is a renowned UK-based engineering company that has been providing turnkey systems, services, and solutions to the food processing industry for over 45 years.

With extensive expertise and experience in both the UK and international markets, Flo-Mech specializes in supplying equipment ranging from individual machines to complete process lines across various food production sectors. Their strength lies in their exceptional project management capabilities, which ensures the successful handling of each contract.

Through collaborations with trusted partner companies, Flo-Mech continues to be a key player in delivering innovative and reliable solutions to meet the evolving needs of the food industry.

About the Flo-Mech Batch Fryer for Chips:

Flo-Mech offers a range of high-efficiency batch fryers designed specifically for the production of hand-cooked, kettle-style crisps with a hard bite. Available in three models—220-240kgs, 140-160kgs, and 100-120kgs—these automatic frying machines are built to cater to varying production needs, with a maximum batch capacity of up to 100kg for the 220 model.

These fryers feature advanced technology, including a high-tech gas modulation burner that ensures 85% energy efficiency and a heat exchanger with an immersion tube style for optimal heat transfer.

The rapid response times of the burners contribute to low CO levels, making the frying process both efficient and environmentally friendly. With cycle times ranging from 400 to 450 seconds, the frying machine equipment minimizes debris build-up due to high turbulence, ensuring cleaner oil and consistent product quality.

2. Fabcon Food Systems Ltd.

Location: 1-3 Delta Close, Norwich, Norfolk NR6 6BG UK

Company Type: Manufacturer

Main Products:

●Vibratory conveyors, seasoning systems, pellet fryers, batch fryers for chips, horizontal motion conveyors, belt conveyors and elevators, general processing equipment.

About the Company:

Fabcon Food Systems Ltd is a leading manufacturer and supplier of bespoke handling and process solutions for the food industry. With a wealth of knowledge and over many years of experience, Fabcon designs, manufactures, installs, and services complete systems tailored to the needs of food processors. The company is committed to delivering high-quality, British-built machinery at competitive prices.

Specializing in a wide range of food processing applications, Fabcon offers innovative solutions for product handling, sorting, precision flavouring, weighing, and packing. From potato chips (crisps) and French fries to frozen foods, vegetables, and pet foods, Fabcon provides complete systems designed for gentle product handling, energy savings, high accuracy, reliability, ease of cleaning, and low maintenance.

About the FFS Potato Crisp/Chip Batch Fryer:

Fabcon Food Systems offers a range of advanced heavy duty batch frying machines designed for the production of hand-cooked, hard-bite artisan-style potato crisps/chips, with capacities ranging from 120 kg/hr to 300 kg/hr of finished product. These fryers are engineered to provide high efficiency, low running costs, and exceptional energy savings, making them an ideal solution for both small and large-scale production.

Featuring a high-tech gas modulation burner, Fabcon’s commercial frying machines achieve an impressive 85% energy efficiency. Their immersion tube-style heat exchangers and rapid burner response times ensure low CO emissions and consistent performance.

3. Taibo Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Produce washing equipment, meat processing equipment, dough processing equipment, carrot washer, beetroot cutting machine, conical rounder machine, electric frying machine for fish and chips, burger patty, onion, doughnut, frying machine gas type, etc.

About the Company:

Founded in 2013, Taibo Machine specializes in the research, development, manufacturing, sales, and after-sales service of a wide range of food processing machines. Their equipment covers various food processing stages, including washing, peeling, cutting, drying, dehydrating, sorting, and grading. Taibo Machine’s products are designed to process a variety of materials such as vegetables, fruits, meat, and dough.

With a mission of “Good Machine Good Food,” Taibo Machine has provided professional machines and services to customers in over 106 countries, becoming a leading enterprise in the food processing industry in China.

About the Taibo Industrial Frying Machine:

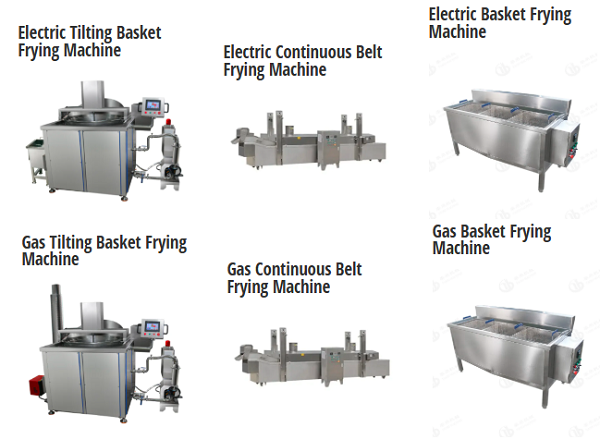

Taibo industrial frying machines are designed to meet the needs of various food processing applications, offering heavy duty, high-quality, efficient, and consistent frying results. Taibo provides a range of industrial and commercial frying machines, including electric and gas-powered options, to cater to different production scales and requirements.

(Click to Know More)

These machines are made of SUS304 stainless steel, making them durable and corrosion-resistant. They feature precise temperature control, adjustable settings, and a dual-layer conveyor belt to prevent materials from floating and ensure uniform frying.

Taibo continuous frying machines and frying machines for restaurant are suitable for a variety of products, including French fries, potato chips, puffed snacks, meat, seafood, pastries, and nuts. With their superior performance and efficiency, Taibo frying machines are a reliable choice for various food processing industries, such as fish and chips, doughnuts, burgers, broasted chicken, garri, onions, and more.

4. L & G Engineering

Location: Unit 14 Ramirez Road, Rackheath Industrial Estate, Rackheath, Norwich, Norfolk, NR13 6GD, UK

Company Type: Manufacturer

Year Founded: 2005

Main Products:

●Batch and continuous fryers, infeed systems, oil filters, seasoning equipment, bespoke projects, gas installations, heating and cooling equipment.

About the Company:

L & G Engineering, founded in 2005, has since grown into a successful business known for its high-quality fryers and seasoning systems. Over the years, the company has expanded to larger premises, better suited to meet the needs of its prestigious customer base.

Specializing in the development of fryers and seasoning systems for hand-cooked crisps and snacks, L & G Engineering has become a trusted partner for both small artisan producers and large-scale food manufacturers. Whether you’re creating small batches with a unique flavor profile or managing a high-volume production line, L & G Engineering ensures your manufacturing process runs smoothly, with minimal downtime and consistent, reliable performance.

About the L & G Engineering Continuous Frying Machine:

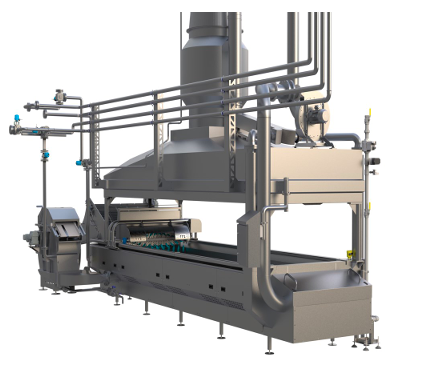

Continuous frying machines are designed for high-efficiency, round-the-clock frying of a variety of food products, including potato chips, peas, nuts, noodles, as well as meat and fish items. These fryers offer a continuous production process, making them ideal for businesses needing to operate 24/7.

Available in various sizes to meet your specific product and output requirements, continuous fryers come equipped with advanced PLC controls, allowing you to monitor and manage the entire cooking process. The control system gives you the ability to oversee oil levels with auto fill and top-up functionality, monitor combustion system health, and track pressure levels. Data recording and logging are also integrated into the system for efficient management.

Conclusion

As we’ve seen, the frying machine industry is populated by a diverse group of manufacturers, each offering unique strengths and solutions. Whether you’re in the market for a batch fryer, a continuous fryer, or any other type of food processing equipment, these manufacturers have the expertise and products to meet your needs.

Ready to take your food processing to the next level? Explore the offerings from these top manufacturers and choose the frying machine that best suits your needs. Your journey to better, more efficient frying starts now!

More to Read

●A Complete Guide to Industrial Frying Machines for Efficient Food

●Best 5 Industrial Frying Machine Manufacturers in the United States

●What Are the Machines Used for Meat Production?

●The Ultimate Guide to Choose the Right Industrial Meat Stuffing Mixer

●The Cutting-Edge of Efficiency: Industrial Fruit Cutting Machines

2 回复