Ⅰ. Introduction to Vacuum Food Tumblers

What is a Vacuum Food Tumbler?

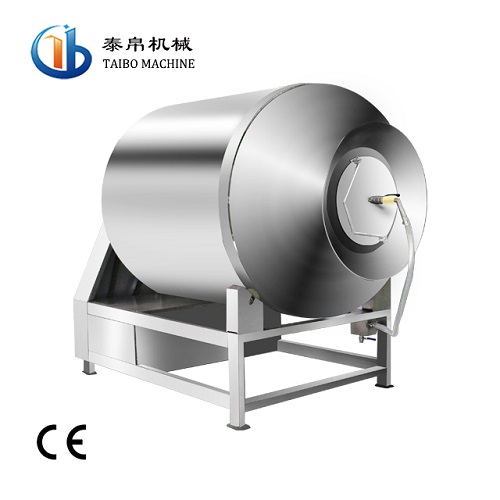

An industrial vacuum food tumbler is an essential piece of equipment in modern food processing, especially meat processing, designed to enhance the flavor, texture, and tenderness of meats, poultry, seafood, and other food products.

By using vacuum technology, these tumblers create a sealed environment that allows marinades and seasonings to penetrate deeply into the food, ensuring uniform flavor and texture.

Importance in the Food Industry

In today’s competitive food industry, the quality and consistency of products are crucial. Vacuum tumbling has become a game-changer, helping businesses streamline their processes, improve product quality, and enhance customer satisfaction. From small artisanal producers to large-scale manufacturers, vacuum tumblers for meat are revolutionizing food preparation and processing.

Ⅱ. Benefits of Using a Vacuum Food Tumbler

1. Enhanced Flavor and Texture

One of the standout benefits of vacuum tumblers is their ability to infuse flavors deeply into food. By creating a vacuum, the tumbler removes air from the chamber, causing the food to absorb marinades and spices more effectively. This process not only enhances the flavor profile but also improves the texture, making meats more tender and succulent.

2. Increased Efficiency

Vacuum tumblers for meat processing significantly speed up the marination process, reducing the time required to achieve optimal flavor infusion. This efficiency translates to higher production rates and reduced labor costs, making it a valuable asset for any food processing operation. With faster marination, businesses can meet production targets without compromising on quality.

3. Consistency and Quality Control

Consistency is key in the food industry. Vacuum meat tumbler ensures that each batch of food is marinated to the same standard, eliminating variations in flavor and texture. This level of control enhances product quality, reduces waste, and improves customer satisfaction, making it easier for businesses to maintain high standards across all their products.

Ⅲ. Applications of Vacuum Food Tumblers

1. Marinating Meats

Industrial tumblers for meat processing are particularly effective for marinating meats, from beef and pork to lamb and poultry. The vacuum process helps the marinade penetrate deeper into the meat fibers, resulting in more intense flavors and improved tenderness. For instance, a beef steak marinated in a vacuum tumbler will have a more robust flavor and juicier texture compared to traditional marinating methods.

2. Processing Poultry and Seafood

Poultry and seafood benefit immensely from vacuum tumbling. The vacuum environment helps in tenderizing these delicate proteins, enhancing their flavor absorption and maintaining their natural moisture. This is especially beneficial for products like chicken breasts, shrimp, and fish fillets, which can become tough and dry if not properly marinated.

3. Use in Ready-to-Eat Meals

The convenience of ready-to-eat meals is increasingly popular, and vacuum tumblers play a crucial role in their preparation. By ensuring even distribution of seasonings and marinades, vacuum tumbling enhances the flavor and texture of pre-cooked meals, making them more appealing and delicious. This process also helps in maintaining the nutritional value and freshness of the ingredients.

Ⅳ. Features to Look for in an Industrial Vacuum Food Tumbler

1. Capacity and Size Options

Choosing the right size and capacity is essential for optimizing your production line. Whether you need a compact tumbler for small batches or a large-capacity model for high-volume processing, there are options available to suit every need. Consider the scale of your operation and the types of products you process when selecting the ideal tumbler.

2. Material and Build Quality

Durability and hygiene are paramount in food processing equipment. Look for vacuum food tumblers made from high-quality, food-grade SUS304 stainless steel, which ensures longevity and easy cleaning. Our tumblers are designed to meet stringent food safety standards, providing peace of mind and reliable performance.

3. Ease of Use and Maintenance

A user-friendly interface and straightforward maintenance are crucial for minimizing downtime. Our vacuum tumblers feature intuitive controls and easy-to-clean components, reducing the time and effort required for operation and maintenance. This ensures that your production runs smoothly without interruptions.

Ⅴ. Why Choose Our Vacuum Food Tumbler?

Our food grade mixer tumblers stand out due to cutting-edge technology and a host of features that ensure optimal performance, durability, and ease of use.

1. Premium Materials

The entire machine, including the drum and frame, is constructed from 304 stainless steel. This material is not only corrosion-resistant but also meets stringent food safety standards.

Unlike some competitors who use cost-saving 201/202 stainless steel for the drum or only employ 304 stainless steel for the head, our tumbler prioritizes quality and longevity.

2. Sturdy Design

The thickened drum and reinforced frame, both made of 304 stainless steel, guarantee no deformation and extend the machine’s service life.

3. High-Quality Vacuum Pump

Our branded vacuum pump ensures consistent vacuum levels, resulting in superior tumbling effects.

4. Precision Engineering

Ingenious welding, processing, and assembly techniques contribute to the machine’s stable performance.

5. Smooth Operation

The soft start feature of the frequency converter ensures seamless machine operation.

6. Power-Off Memory Function

If the machine is unexpectedly disconnected during tumbling, the computer controller automatically memorizes the time. Upon power-on, pressing the “Tumble” button resumes tumbling based on the previous duration.

7. Customer Support and Service

We are committed to assisting our customers at every stage. From installation and training to ongoing technical support, our dedicated team ensures that your investment in our vacuum food marinator tumbler is protected and reliable.

Additionally, our tumbler boasts specific design elements:

1. Round Head

With a reasonable structure and ample tumbling space, the finely polished inner surface of the drum ensures complete material discharge and eliminates hidden corners for optimal sanitation.

2. Arc-Shaped Paddles

Uniquely designed paddles evenly distribute marinade without compromising product appearance. This enhances softness and overall product quality.

3. Customizable Controls

Users can freely set automatic clockwise and anticlockwise rotations, intervals, deflation, and vacuum levels based on their specific processing needs.

FAQs

● What types of food can be processed in a vacuum food tumbler machine?

Vacuum tumblers are ideal for meats, poultry, seafood, vegetables, and even ready-to-eat meals.

●How long does the marination process take?

The time varies depending on the product and marinade, but vacuum tumbling typically reduces marination time to a fraction of traditional methods.

●Is maintenance difficult?

Our tumblers are designed for easy maintenance, with simple cleaning procedures and minimal moving parts.

●How does vacuum tumbling improve food safety?

The vacuum process reduces the risk of contamination and ensures even marination, which helps maintain high hygiene standards.

●Can I customize the settings on the vacuum food tumbler?

Yes, our tumblers come with customizable settings to suit different types of food and marination requirements.

Conclusion

offering unparalleled benefits in flavor enhancement, efficiency, and quality control. If you are a large-scale manufacturer, incorporating a vacuum food tumbler into your operations can elevate your products and boost your business’s success.

Ready to take your food processing to the next level? Contact us today to learn more about our vacuum food tumblers and meat processing equipment.

More to Read

●The Essential Guide to Industrial Frozen Meat Processing Equipment

●Top 5 Industrial Vacuum Meat Tumbler Manufacturers in Europe

●Best 5 Industrial Vacuum Meat Tumbler Manufacturers in Poland

●Top 4 Industrial Vacuum Meat Tumbler Manufacturers in Canada