Introduction

Beetroot processing is a crucial step in various industries, from food manufacturing to packaging. The right equipment ensures efficiency, consistency, and high-quality results.

In this guide, we’ll explore the different types of beetroot equipment available, including peeling machines, cutting machines, dicing machines, and more.

If you’re looking to streamline your beetroot processing operations, this blog will give you all the information you need to choose the best machines for your needs.

Ⅰ. What is Beetroot Processing?

Beetroot processing refers to the steps involved in preparing beetroots for use in food production, including peeling, washing, cutting, dicing, and slicing. These processes require specialized equipment to ensure efficiency, reduce waste, and maintain product quality.

For large-scale operations, automation is key to optimizing production time and maintaining consistent product standards. Whether you’re working in restaurants, or large food processing plants, the right beetroot equipment makes a huge difference in overall performance.

Ⅱ. Essential Beetroot Equipment for Processing

Beetroot processing involves several key steps, and each step requires specialized machines designed for optimal performance. From peeling and washing to slicing and dicing, each piece of beetroot equipment plays a critical role in improving productivity and quality.

Taibo Machine manufactures high-quality beetroot processing equipment that ensures a smooth, efficient, and cost-effective production line for all stages of beetroot processing.

1. Beetroot Washing Machines

Beetroot washing is the first step in the processing line and is essential for ensuring that the beetroots are clean and free from soil or other contaminants.

Taibo Machine’s beetroot washing machines are designed to effectively remove dirt, debris, and residues from the surface of the beetroots without damaging them. Featuring advanced bubble washing, vortex washing and water-spraying systems, these washing machines thoroughly clean large volumes of beetroots quickly and efficiently. These beetroot washing machines are constructed with high-quality SUS304 stainless steel for durability, ensuring long-lasting performance in industrial settings.

(Click to Read More)

Our beetroot washing machines are also designed to integrate seamlessly into existing production lines, making them ideal for both small-scale operations and large-scale production facilities.

2. Beetroot Peeling Machines

Peeling is a time-consuming task, especially when processing large quantities of beetroots. Taibo Machine’s beetroot peeling machines solve this challenge by automating the peeling process, removing the tough outer skin in just a few seconds.

These machines use an abrasive rollers and brush rollers to ensure minimal wastage while preserving the integrity of the beetroot. With adjustable peeling settings, the machines can both wash and peel, giving operators flexibility based on the specific requirements of their product.

Additionally, Taibo’s beetroot peeling machines are designed for high-volume operations, ensuring efficiency and consistency. The automation of the peeling process not only reduces labor costs but also increases productivity, making these peeling machines an essential part of modern beetroot processing.

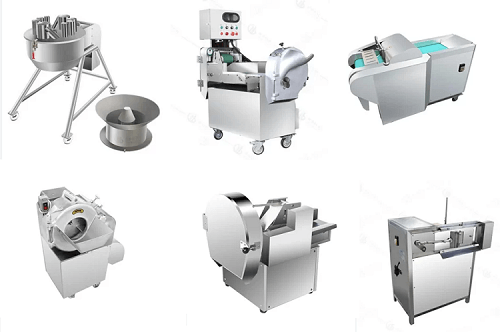

3. Beetroot Cutting Machines

The beetroot cutting machines from Taibo Machine are designed to handle various cutting tasks with precision. Whether you’re looking to slice, dice, or julienne beetroots, these machines deliver uniform and consistent results every time.

Taibo’s cutting machines are engineered for easy operation and high-speed processing, ensuring that beetroots are prepared quickly and with minimal waste. The versatility of these machines makes them perfect for a variety of applications, including potatoes, cassavas, sweet potatoes, carrots, onions and other vegetables and fruits.

(Click to Read More)

With robust construction and simple controls, Taibo’s beetroot cutting machines ensure reliability and durability, even in high-demand industrial environments.

4. Beetroot Slicing Machines

For applications such as salads, garnishes, or ready-to-eat meals, consistent and uniform beetroot slices are crucial. Taibo Machine’s beetroot slicers are designed to create thin, even slices at high speeds. \

Built with precision engineering, these slicers ensure that each beetroot is sliced into perfect pieces that meet the exact specifications for various food products. The industrial beetroot slicers are easy to adjust for different thicknesses, making them versatile for a range of slicing needs. With durable stainless steel components, these slicers are built to last and can handle high volumes of beetroots with ease.

Whether you need slices for fresh salads, pre-packaged meals, or garnishes, Taibo’s beetroot slicers provide consistent quality and help streamline the production process.

5. Beetroot Dicing Machines

When it comes to preparing beetroots for soups, salads, or other value-added products, dicing is often required. Taibo Machine’s beetroot dicing machines are designed to create perfectly uniform cubes or chunks with minimal waste. These dicing machines can handle both small and large batches of beetroots, offering high precision and consistent results.

Whether you’re creating beetroot cubes for packaged meals or ingredients for other food products, these machines provide the necessary flexibility and speed to meet production demands.

With easy-to-clean designs and high-efficiency motors, Taibo’s beetroot dicing machines ensure reliability and durability in large-scale food processing operations.

6. Root Vegetable Handling Systems

Taibo Machine also offers root vegetable processing lines, which include beetroot washing peeling air-drying production line, vegetable fruit washing slicing dehydrating line and so on. These production lines are designed to automate the movement and handling of beetroots as they pass through various stages of processing. These handling systems can seamlessly integrate with other beetroot equipment, such as washing, peeling, and cutting machines.

(Click to Read More)

By automating the transportation of beetroots by lifting machine and conveying machine, the beetroot handling systems reduce labor costs, minimize downtime, and enhance overall production efficiency.

Taibo’s root vegetable processing lines are built with sturdy materials and designed for easy maintenance, ensuring reliable operation in busy production environments. These production lines help maintain the flow of production and keep the beetroot processing running smoothly, increasing throughput and ensuring timely delivery of finished products.

Ⅲ. How to Choose the Right Beetroot Equipment for Your Needs

When selecting beetroot equipment, there are 4 factors to consider:

1. Volume Requirements

Choose machines that can handle your beetroot production capacity. Large-scale operations will require high-volume equipment, while smaller businesses may need machines that are more compact.

2. Efficiency and Speed

Look for equipment that offers quick processing times to improve productivity.

3. Ease of Use and Maintenance

Choose beetroot machines that are easy to operate and maintain. Machines with simple controls and low-maintenance designs are ideal for long-term operations.

4. Durability and Build Quality

Invest in equipment made from high-quality materials, such as stainless steel, which can withstand the rigors of continuous use.

Beetroot washing machines, peeling machine, cutting machines, slicing machines and dicing machines all have different features tailored to specific needs. It’s important to assess your operation’s requirements before making a decision.

Ⅳ. Taibo Machine: Your Trusted Beetroot Machine Manufacturer

Taibo Machine is a leading manufacturer of beetroot equipment, including beetroot washing peeling machines, cutting machines, and dicing equipment. Our machines are designed for high efficiency, durability, and ease of use, ensuring that your beetroot processing operation runs smoothly.

With years of experience in manufacturing top-quality beetroot equipment, Taibo Machine provides tailored solutions to meet the needs of various scales, from medium scale to large scale. Our machines are built with the latest technology to guarantee precision and consistency, helping you achieve the best results.

Conclusion

Beetroot processing requires specialized equipment to handle the various tasks involved, from peeling and cutting to dicing and slicing. Investing in high-quality beetroot equipment ensures efficiency, consistency, and higher productivity.

Whether you’re looking for beetroot washing peeling machines, slicing machines, or dicing equipment, Taibo Machine offers a wide range of solutions designed to meet the demands of your production line.

Contact us today to learn more about how we can help streamline your beetroot processing operations.

More to Read

●What Are Different Types of Industrial Vegetable Washers?

●The Essential Guide to Cutting Machines for Food: Efficiency and Precision

●Explore the Price Range of Food Washing Machines: Factors to Consider

●Efficient Beetroot Processing: Master Food Manufacturing with Beetroot Cutting Machine

●Top 8 Industrial Food Dicing Equipment Manufacturers Worldwide

2 回复