Introduction

Germany is home to some of the world’s most respected manufacturers of large industrial meat grinders. These meat grinders are widely used in meat processing plants, food factories, and large-scale production lines across the globe.

In this blog, we take a closer look at several leading manufacturers of heavy-duty meat grinders in Germany—including Kolbe Foodtec, GLASS GmbH & Co KG, Taibo Machine and Maschinenfabrik Seydelmann KG.

Whether you’re upgrading your production equipment, expanding capacity, or searching for a reliable long-term supplier, this guide will help you understand each manufacturer’s strengths and the grinder solutions they offer.

1. Kolbe Foodtec

Location: Gewerbestraße 5, 89275 Elchingen, Germany

Company Type: Manufacturer

Year Founded: 1949

Main Products:

●Bandsaws, manual mincers, mixer grinders and portioning solutions, automatic crossfeed grinder, dynamic separating system.

About the Company:

Kolbe Foodtec is a renowned German manufacturer specializing in premium, high-quality meat-processing machines. All production is carried out exclusively at its own facility in Elchingen, Germany, allowing the company to maintain complete control over quality, precision, and manufacturing standards. This centralized production approach ensures consistently reliable performance and outstanding durability across all products.

With advanced technology and the highest hygiene standards, Kolbe Foodtec offers a comprehensive range of solutions for meat and fish processing, serving businesses of all sizes worldwide. Continuous innovation and in-house production enable the company to respond flexibly to individual customer requirements and to deliver customized solutions for diverse processing needs.

About the Kolbe Meat Mixer Mincer:

This meat mixer mincer is one of the larger, high-performance mixer mincers designed for portioning and large-batch meat processing. It is specially engineered to process large meat pieces effortlessly, even at product temperatures down to -6 °C. This strong performance is achieved through its oversized cutting system and the robust dimension of the worm, which ensure smooth, stable operation and consistent product quality under demanding industrial conditions.

This meat mincer is widely used in applications where large batch sizes are required. With a hopper volume of 120 liters and a typical batch size of approximately 100 kg, it is ideal for medium to large meat-processing facilities that require high efficiency and continuous production. Depending on the product and cutting set, the machine can achieve an output of up to approximately 2000 kg per hour, making it well-suited for high-volume operations.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Centrifugal deoiling machine, vegetable grading equipment, vegetable peeling and cutting machinery, meat bowl chopper, batch frying machinery, industrial fruit washer, dough rounder machines.

About the Company:

Taibo Machine is a trusted manufacturer of modern food-processing equipment, providing reliable solutions for global food industries. The company specializes in machines designed to improve efficiency, consistency, and hygiene across meat processing, vegetable and fruit processing, snack production, and bakery preparation. Over the years, Taibo has built a solid reputation for delivering durable, user-friendly, and cost-effective machinery that meets the production needs of both small food workshops and large industrial plants.

At Taibo, every machine is engineered with careful attention to detail. From meat grinders, bowl cutters, tumblers, and meat mixers to vegetable washing machines, cutting machines, blanching systems, potato-chips equipment, dough dividers, dough rounders, and many other processing lines, Taibo strives to provide complete, flexible, and customized solutions.

About the Taibo Meat Grinder:

(Click to read more)

The industrial meat grinder from Taibo is a robust and flexible solution for large-scale meat processing, designed to handle fresh or frozen meat (or other meat-based products) with high efficiency and hygiene. The grinder is built from food-grade SUS 304 stainless steel, ensuring corrosion resistance, durability, and compliance with food safety standards.

Taibo offers a full range of models with capacities ranging from around 300–500 kg/h up to 3000–5000 kg/h, making the grinder suitable for small butcher shops, mid-sized meat processors, and large industrial plants alike.

3. GLASS GmbH & Co KG

Location: Frankfurter Weg 28 33106, Paderborn, Germany

Company Type: Manufacturer

Year Founded: 1972

Main Products:

●Food mixers, food grinder, temperature control machines, emulsifier, schnitzel flattener, industrial tumblers, industrial frying machines, meat tenderizer, cooking machines, cooling blender, vacuum mixer, batch mixer.

About the Company:

GLASS GmbH & Co. KG is a German specialist in mixers, process plants, and food processing machinery with more than 50 years of experience in the industry. As a third-generation family business, the company stands for durability, reliability, flexibility, state-of-the-art technology, and the highest standards of hygiene.

GLASS focuses on the design and manufacture of custom-made machines that are precisely tailored to the individual needs of each customer. Its product range includes food mixers, meat processing machines, temperature control systems, cooking systems, and fine choppers. With deep application expertise and strong engineering capabilities, GLASS is able to develop optimal solutions for a wide variety of food processing tasks and acts as a reliable partner for process optimization across the global food industry.

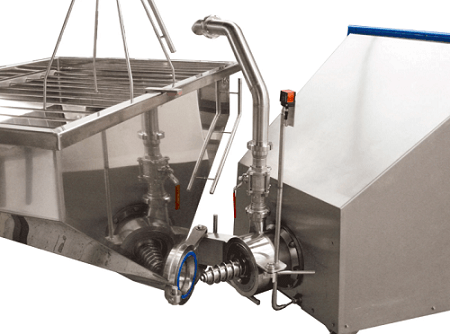

About the GLASS Food Grinder:

This food grinder is designed for continuous comminution and emulsification in demanding food processing applications. Designed for precise and reliable fine cutting, the machine delivers consistent product quality with excellent structural preservation. Its advanced design makes it ideal for meat, emulsions, sauces, and other fine food products that require uniform particle size and smooth texture.

Designed for efficiency and ease of use, the cutting system allows for easy assembly and disassembly, significantly reducing cleaning and maintenance time. Temperature monitoring ensures stable operation and high production reliability, protecting both the product and the machine during continuous operation. In addition, the encapsulated motor provides superior protection and long service life, even under heavy industrial workloads.

4. Maschinenfabrik Seydelmann KG

Location: Hölderlinstraße 9, DE-70174 Stuttgart, Germany

Company Type: Manufacturer

Year Founded: 1843

Main Products:

●High efficiency cutter, vacuum cutter, automatic grinder, frozen meat grinder, mixer, mixer-grinder, vacuum massager, trolley tumbler, emulsifier, production line.

About the Company:

Maschinenfabrik Seydelmann KG is a historic and globally respected manufacturer of high-performance food-processing machinery.

For over 180 years, Seydelmann has specialized in the development, design and manufacturing of advanced cutters, mixers, grinders, emulsifiers and complete production lines for the food industry. Their machines serve a broad spectrum of applications: traditionally, meat and sausage processing, but increasingly also modern sectors such as plant-based meat substitutes, dairy, fish, vegetables, confectionery, soups, bakery, baby food, and even pharmaceutical production.

Seydelmann machines stand out for their high build quality, robust stainless-steel construction, and technical sophistication. Through ongoing innovation — such as vacuum cutters, fine-grinding systems, and fully automated production lines — the company has established itself as a worldwide leader.

About the Seydelmann Automatic Grinder:

This automatic grinder is a high-efficiency industrial grinder designed to deliver powerful, reliable, and hygienic meat processing performance. Built to meet the highest quality standards, this robust machine ensures optimal results for demanding production environments. With a 114 mm hole plate, a strong motor, and an impressive hourly output of 1500 kg/h, the grinder machine offers both speed and precision for continuous operation.

Equipped with a 2-speed working worm and a wide conical feeding worm, the machine handles fresh, frozen, and slightly frozen meat with ease. It also processes cooked products, liver, spinach, and other foods efficiently. Large pieces of product are gently guided into the working worm without forming bridges, ensuring fast, uniform, and safe grinding. A safety guard with switch-off contact prevents accidental access to the feeding area.

Conclusion

Choosing the right meat grinder manufacturer and meat grinders made in Germany is essential for achieving consistent product quality, higher yields, and long-term reliability in your processing line.

No matter the size of your facility or your production requirements, the met processing equipment manufacturers in this guide offer proven solutions that can help you optimize output and improve product consistency.

If you’re looking for a reliable industrial meat grinder or need help selecting the right model, contact Taibo Machine today for expert guidance and tailored equipment recommendations.

More to Read

●Top 4 Industrial Meat Block Grinders Manufacturers Worldwide

●Everything You Need to Know about Industrial Meat Block Grinder

●Top 4 Frozen Meat Block Flaker Manufacturers Worldwide

●Top 4 Fruit Vegetable Processing Equipment Manufacturers and Suppliers in Africa

一个回复