Introduction

The Netherlands is home to some of the most advanced vegetable and fruit grading equipment manufacturers in the world. From sorting and weighing machines to complete automation solutions, these companies deliver technology that improves efficiency, reduces labor, and ensures consistent product quality for growers and processors worldwide.

In this blog, we highlight four leading names in the equipment for grading of fruits and vegetables — Taibo Food Machine, Burg Machinery, TAKS Handling Systems, and Key Technology. Whether you’re looking for precision weight graders, automated sorting lines, or integrated handling systems, these manufacturers represent the best of innovation and reliability in food processing.

1. Burg Machinery

Location: Weihoek 11, 4416 PX Kruiningen, Nederland

Company Type: Manufacturer

Year Founded: 1954

Main Products:

●Supply optimiser, goods elevator, inspection belt, conveyor belt, fruit wax line, brush dryer, bin washer, broccoli sorting machine, fruit elevator, dryer, multi head weigher, pumpkin sorting machine with weighing function.

About the Company:

Founded in 1954, Burg Machinery has built a long-standing reputation as a trusted manufacturer of reliable and efficient machines for the fruit processing and agricultural industries.

Over the past 30 years, Burg has expanded its expertise beyond fruit processing to include logistics automation for a variety of agricultural sectors. Today, the company designs and produces a comprehensive range of machines, from infeed robot emptying systems to advanced palletisers, tailored for sorting and packaging companies worldwide.

Driven by the mission to provide the best possible automation and optimization solutions, Burg Machinery supports customers in every stage of fruit and vegetable sorting, packaging, and logistics. Their commitment extends beyond machine delivery, offering complete project management, service, and maintenance support to ensure seamless operation and long-term performance.

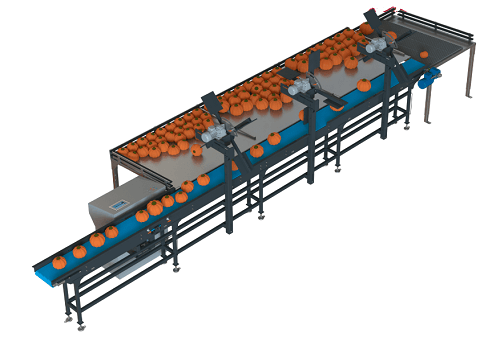

About the Burg Machinery Pumpkin Sorting Machine:

The pumpkin sorting machine with weighing function is developed for efficiently sorting and weighing pumpkins in modern processing lines.

It features a modular construction and adjustable speed settings, making it adaptable to different production capacities and layout configurations. Its automated system replaces manual operations, improving efficiency and reducing labor costs. Built with durability and reliability in mind, this produce grading equipment can be seamlessly integrated into complete pumpkin supply and sorting lines, ensuring smooth and continuous operation.

The pumpkin sorting machine is commonly used in various projects, including supply and sorting lines for pumpkins, sorting lines, and sorting machine installations. With its combination of precision weighing, modular design, and automation, it provides an ideal solution for businesses seeking to enhance the efficiency and quality of their pumpkin processing operations.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Vegetable grading equipment, vegetable peeling and cutting machinery, deoiling machine, industrial fruit washer, fruit grading equipment, batch frying machinery, carrot processing line, vegetable sizing machine, vortex washing machine, beetroot slicer machine.

About the Company:

Taibo Machine is a professional manufacturer and exporter of industrial food processing machinery, dedicated to delivering reliable, efficient, and innovative equipment solutions for global customers. With years of experience in research, development, and production, Taibo Machine specializes in a wide range of machines used in the meat processing, vegetable and fruit processing, snack food, and bakery industries.

From automatic meat processing machines such as bowl cutters, meat tumblers, and flakers, to complete potato chips production lines, vegetable washing systems, and dough processing equipment, Taibo Machine provides intelligent automation solutions designed to improve productivity, hygiene, and consistency. Every machine is built with high-quality SUS304 stainless steel and advanced control systems to ensure durability, food safety, and easy maintenance.

About the Taibo Food Safe Size Grading Machine:

The automatic fruit and vegetable weight grading machine is built to sort fruits and vegetables based on weight. It features advanced weighing technology to deliver consistent, accurate grading across multiple weight categories. For instance, processors sort apples, pears, onions, lemons, and other round or near-round produce using this type of machine, which streamlines classification and reduces manual labour.

(Click to Learn More)

Key benefits of this pear grading machine include high throughput, excellent accuracy, minimal damage to sensitive produce, labour savings, and improved quality control. One of the advantages is that the machine can be re-adjusted easily to fit different weight ranges or product types, adding versatility in multi-product operations.

Because food-safety and sanitation are critical, the machine is typically constructed with food-grade stainless steel, has hygienic design features for easy cleaning, and low maintenance requirements. The smooth operation and durability make it ideal for packing houses, processing plants, and distribution centres handling fresh produce.

3. TAKS HANDLING SYSTEMS B.V.

Location: Munnikenheiweg 58, 4879 NG Etten-Leur, The Netherlands

Company Type: Manufacturer

Year Founded: 1988

Solutions:

●Transport, sorting, weighing, packaging, palletizing, software, complete packing halls.

Markets:

●Tomatoes, cherry tomatoes, cucumbers, mini cucumbers, bell peppers, eggplants, fresh produce, strawberries and soft fruits, mushrooms, potatoes, onions and carrots, apples and pears, other fruits and vegetables.

About the Company:

For decades, TAKS Handling Systems has been a trusted name in innovative internal transport and product processing solutions. The company specializes in designing, manufacturing, and assembling high-quality automation systems for the greenhouse industry, the fruit and vegetable sector, and various material handling applications worldwide.

The company’s success is built on a strong commitment to quality, innovation, and flexibility. By offering modular and custom-built systems, TAKS enables businesses to adapt and expand their post-harvest and material handling processes with ease. Whether it’s optimizing fruit and vegetable processing or enhancing internal logistics in other industries, their automation systems are engineered for long-lasting performance and future growth.

From concept to completion, TAKS Handling Systems delivers automation that works, providing customers around the world with reliable, high-performance internal transport and processing solutions that drive efficiency and growth.

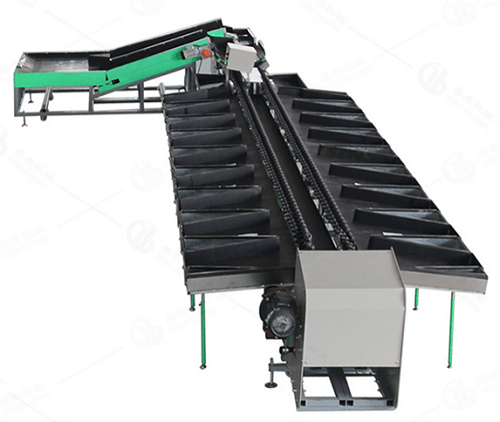

About the TAKS Sorting Solution:

At TAKS Handling Systems, sorting is not just an add-on, it’s a core part of the automation journey. Whether you’re looking for a fully automated sorting machine or modular tables and conveyors to assist manual grading, TAKS offers a wide spectrum of solutions tailored to your needs. From conveyors and grading tables to advanced automatic sorters, every module is designed to integrate with internal transport systems and material-handling flows.

Working in close collaboration with carefully selected partners, TAKS designs sorting solutions that meet your exact requirements. The approach begins with an assessment of your production layout, output targets, labour constraints and future growth. From there, TAKS configures the right modules to create a comprehensive system.

Whether you are processing greenhouse produce, fruit and vegetables, or handling material flows in other sectors, TAKS’ sorting solution is built to deliver speed, efficiency and labour savings.

4. Key Technology

Location: Beijerdstraat 10 4112 NE, Beusichem The Netherlands

Company Type: Manufacturer

Year Founded: 1948

Main Products:

●Collection conveyors, grading, sizing, separating conveyors, precision size grader, length sizer, diameter sizer, rotary sizing and grading systems, optical sorters, whole potato optical sorter, data analytics software.

About the Company:

Key Technology is a globally recognised leader in the design and manufacture of automation systems for the food-processing industry. Their expertise spans optical sorters, conveyors and integrated processing equipment, all engineered to help food processors improve product quality, increase yield and reduce manual labour.

With more than 75 years of experience, Key Technology serves a wide range of segments including fresh and frozen fruits and vegetables, nuts, snacks, potato, and confectionery. Their solutions combine advanced inspection technologies with smart conveying and processing systems, all designed to deliver reliable performance, high throughput and food-safety compliance.

Key Technology emphasises its commitment to being the ultimate partner of choice for food-processing companies. They offer not only machines but full integrated solutions: sorting, grading, conveying and processing, backed by strong service and lifecycle support.

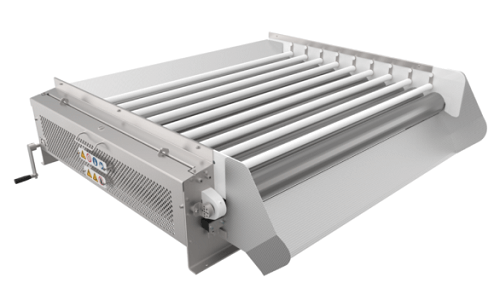

About the Key Technology Precision Size Grader:

The precision size grader is an advanced, food-grade sizing machine engineered to accurately grade delicate food products by diameter. Designed for precision, reliability, and gentle product handling, this vegetable fruit grading machine delivers uniform size separation while minimizing product damage, making it ideal for fruits, berries, vegetables, and other damage-sensitive products.

At the heart of this carrot grading machine is a unique combination of precision-machined stainless steel rollers and a pinch-eliminating drive system. The adjustable gap between the rollers determines the target size: correctly sized products fall through the rollers, while larger ones continue over the top for further processing. With progressively increasing roller speeds along the machine’s length, products spread into a single layer for highly accurate, consistent grading.

This grading machine is built with efficiency and simplicity in mind. It offers on-the-fly adjustability, enabling operators to fine-tune sizing quickly and accurately without interrupting production.

Conclusion

The Dutch fruit and vegetable processing industry continues to set global standards for efficiency, quality, and technological excellence. Whether you operate a small processing unit or a large-scale production facility, investing in the right vegetable fruit grading equipment is key to achieving greater profitability.

If you’re ready to upgrade your vegetable and fruit processing line with reliable and high-performance equipment, contact Taibo Machine today. Our team of experts can help you design a complete solution that ensures your business stays ahead in a competitive market.

More to Read

●Best 4 Vegetable Fruit Grading Equipment Manufacturers in the Netherlands

●Top 4 Industrial Vegetable Fruit Grading Equipment Manufacturers in Australia

●Top 8 Industrial Food Dicing Equipment Manufacturers Worldwide

●Top 7 Industrial Vegetable Washer Manufacturers in the World