Introduction

In the competitive world of food processing, choosing the right meat bowl cutter manufacturer can make a significant difference in product quality, production efficiency, and overall business success. Whether you’re producing finely emulsified sausages, plant-based proteins, or mixed meat products, a high-performance bowl cutter is an essential tool for achieving consistent texture, flavor, and yield.

In this blog, we introduce four reputable manufacturers. From compact machines ideal for small batch production to powerful industrial systems built for continuous operation, these companies are shaping the future of meat and food processing with innovative, high-quality solutions. Read on to discover which manufacturer best suits your production needs.

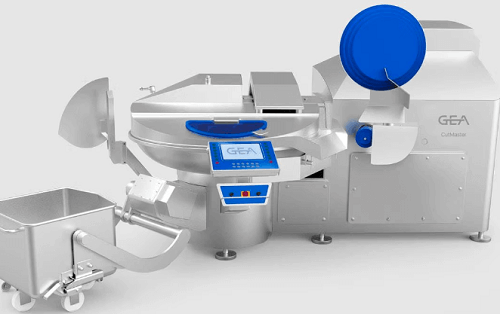

1. GEA

Location: Peter‑Müller‑Straße 12, 40468 Düsseldorf, North Rhine‑Westphalia, Germany.

Company Type: Manufacturer

Year Founded: 1881

Main Products:

●Brine preparation equipment, cooking roasting grilling and smoking equipment, bowl cutter, defrosting and mixing equipment, defrosting and tumbling equipment, fryers and oil treatment solutions, grinding equipment, slicing equipment, tenderizing equipment.

About the Company:

GEA is one of the world’s leading technology suppliers for the food, beverage, and pharmaceutical industries. With a comprehensive portfolio that includes machinery, process technology, components, and services, GEA plays a vital role in optimizing production processes and improving efficiency and sustainability for customers across the globe.

Founded on strong values and a clear purpose—“Engineering for a better world”—GEA combines innovation with responsibility. Its vision is to safeguard future generations by delivering sustainable solutions for essential industries like nutrition and pharmaceuticals. From morning coffee to evening medications, GEA’s technologies are deeply embedded in everyday life, making a positive impact on quality, safety, and environmental stewardship.

About the GEA Bowl Cutter:

The GEA bowl cutter is a powerful, all-in-one bowl cutter designed to cut, mix, and emulsify a wide range of food products with exceptional speed and precision. Engineered for flexibility and user-friendliness, this machine enables food processors to effortlessly switch between ingredients and product types—from coarse chopping to fine emulsions—ensuring consistent results across a diverse portfolio. Whether you’re working with meat, fish, poultry, processed cheese, sauces, or plant-based alternatives, the machine delivers outstanding performance tailored to the modern demands of food production.

At the heart of this bowl cutter is the knife head, which allows the machine to operate at cutting speeds of up to 162 meters per second. This high-speed capability ensures efficient particle reduction, producing smooth emulsions with reliable binding, uniform consistency, and optimal color and taste.

Designed with hygiene and durability in mind, the machine features a compact footprint and is built from high-quality components to guarantee a long service life in demanding production environments.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Meat processing equipment, industrial meat cutting equipment, dough processing equipment, vegetable washing machine, vegetable grading equipment, food cutting equipment, commercial vacuum meat tumbler.

About the Company:

Founded in 2013, Taibo Food Machine has rapidly emerged as a leading global manufacturer of food processing equipment. The company delivers high-quality machinery that covers the entire processing chain — from washing, peeling, grinding, chopping and cutting to drying, dehydrating, sorting, and grading.

Its extensive product line includes vegetable washers and cutters, fruit dryers, meat processing units like bowl choppers, sausage-making machines, and turnkey solutions for bakeries.

With global reach, trusted certifications, and a philosophy rooted in delivering excellence, Taibo Food Machine ensures that machines don’t just function, but elevate your food production from start to finish.

About the Taibo Meat Bowl Chopper:

The Taibo meat bowl chopper machine is designed to finely chop, mix, and emulsify a wide range of food products—including meat, vegetables, fruits, and auxiliary ingredients like ice and water—with impressive efficiency. Utilizing high-speed rotating blades housed in a robust stainless-steel bowl, it delivers consistently fine particles or smooth emulsions, making it ideal for sausages, meatballs, pâtés, and more.

Equipped with variable-frequency technology, the chopper offers precise control of blade and bowl speeds, optimizing both energy usage and processing results. Constructed from food-grade SUS 304 stainless steel, featuring precision CNC machining, imported SKF bearings, and high-quality copper-core motors, this machine combines hygiene, accuracy, and durability to meet demanding food safety standards.

(Click to Read More)

Available in capacities from 20 L to 125 L, with models offering dual-speed or stepless variable blade operation, the meat bowl chopper machine adapts to different batch sizes and product textures.

3. TALSA

Location: Xirivella, Valencia, Spain.

Company Type: Manufacturer

Year Founded: 1900

Main Products:

●Automatic meat fillers, stuffers, mixers, cutters, choppers, mincers, grinders, cookers, kettles.

About the Company:

TALSA is a global market leader in the manufacturing of medium-capacity, high-quality food processing machinery. With a history spanning over a century, TALSA has earned a reputation for engineering excellence and customer satisfaction in the food industry.

Between 2017 and 2019, TALSA launched a new range of machines built with cutting-edge technology and fully compliant with stringent European health and safety regulations. These advancements reflect their extensive industrial experience—over 80 years dedicated specifically to the food and meat processing sector.

The company’s commitment to quality and international reach has been recognized by the Chamber of Commerce of Valencia, which honored them with the Exportation Award.

About the TALSA Industrial Bowl Cutter/Chopper:

This TALSA industrial bowl cutter/chopper is engineered for professionals who demand the highest standards in food processing. Designed for exceptional results with meat, vegetables, vegan/vegetarian products, fish, and specialty doughs, this bowl chopper blends cutting-edge technology with robust construction and user-friendly operation.

Equipped with variable cutting speeds from 500 to 5000 rpm and gentle mixing speeds from 50 to 500 rpm (forward and reverse), this bowl cutter offers unmatched control and versatility. Its German BE-Maschinenmesser knives, made from high-resistance KUT steel, ensure clean, consistent cuts, while the motorized stainless-steel knife lid and transparent noise protection cover enhance both safety and operator comfort.

Whether you’re processing traditional meats or plant-based alternatives, the machine delivers powerful performance, precise control, and maximum efficiency—making it an essential tool for modern food production facilities.

4. K+G Wetter

Location: Goldbergstrasse 21, 35216 Biedenkopf, Germany

Company Type: Manufacturer

Year Founded: 1990

Main Products:

●Bowl cutter, vacuum bowl cutter, grinder, mixer grinder.

About the Company:

At K+G Wetter, perfection is not just a goal—it’s a promise. As a trusted manufacturer of high-quality meat and food processing machines, the company is committed to making production easier, more efficient, and more enjoyable for both operators and end consumers. Whether you’re producing traditional meat products or innovative food alternatives, K+G Wetter machines are built to enhance flavor, increase productivity, and deliver consistent results.

Driven by a passion for technology and precision craftsmanship, K+G Wetter continuously develops advanced machine solutions that meet the evolving demands of the food processing industry. The company doesn’t settle for good enough. Instead, it pushes boundaries with innovative designs that set new standards in performance, hygiene, and user-friendliness.

Whether you’re a small artisan producer or a large-scale industrial operation, K+G Wetter offers a comprehensive product range and expert support to help you find the perfect solution for your specific application.

About the K+G Wetter Bowl Cutter:

Bowl cutters from K+G Wetter are engineered with uncompromising quality to ensure outstanding results in meat processing. Whether you’re a small butcher shop or a large-scale industrial producer, this series offers the perfect balance of strength, stability, and precision to meet your specific production needs.

One of the key features of the bowl cutter is its extremely smooth and quiet operation, made possible by its robust construction and precision-engineered components. The intuitive control interface makes the machine simple and efficient to operate, even during complex processing tasks. Thanks to its advanced bowl design with a raised edge, the cutter offers a very high fill level, allowing users to process more product per batch without the risk of overflow.

The removable baffle plate provides flexibility in adjusting the cutting space, ensuring optimal cutting quality across a wide range of products. Additionally, the integrated temperature sensor positioned directly in the cutting area offers real-time monitoring.

Conclusion

Choosing the right meat bowl cutter is about more than just cutting speed or capacity—it’s about partnering with a manufacturer that understands your production goals, values quality and innovation, and provides reliable support long after the sale.

Ready to invest in a meat bowl cutter that meets your business needs? Explore our recommended manufacturers, compare features, and contact suppliers directly to request a quote or consultation.

More to Read

●Top 4 Sausage Mixer Machine Factories Worldwide

●Top 4 Frozen Meat Block Flaker Manufacturers Worldwide

●Best 5 Industrial Vacuum Meat Tumbler Manufacturers in Poland

一个回复