Introduction

In today’s food processing industry, hygiene and efficiency are more important than ever. Whether you’re running a fruit packaging line, a frozen vegetable factory, or a central kitchen, washing produce thoroughly is a critical step in delivering safe, clean, and high-quality products. That’s where the industrial vortex washing machine comes in—a powerful, water-efficient, and gentle solution designed specifically for washing fruits and vegetables on a large scale.

A. What Is an Industrial Vortex Washing Machine?

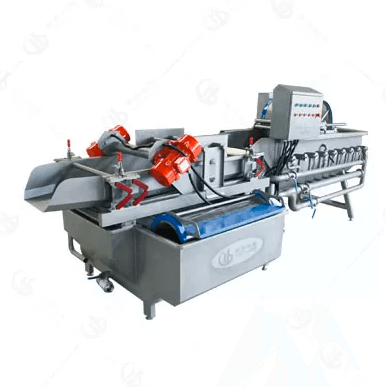

An industrial vortex washing machine is a type of food washing equipment that uses a swirling water flow, or vortex, to clean produce. This vortex movement lifts and removes dirt, sand, pesticide residues, and other impurities from the surface of fruits and vegetables without damaging them.

The machine typically consists of a stainless steel washing tank, water circulation system, pump, and sometimes additional components like air bubble generators or filtration units. The vortex mimics the action of hand washing—effective yet gentle—making it ideal for delicate produce such as leafy greens, strawberries, and tomatoes.

(Click to know more)

B. How Does the Vortex Fruit Washer Work?

The core cleaning process relies on a continuous circular water flow created by a powerful pump system. When produce enters the tank, the swirling water moves it in all directions, helping to loosen and wash away surface contaminants.

Many machines also incorporate air bubble systems for enhanced scrubbing power, ozone sterilization units for microbial control and filtration or sediment removal systems to keep the water cleaner for longer use.

The machine may also feature an automatic discharge system to remove cleaned produce and residue water separately, reducing manual labor and processing time.

C. Key Benefits of Vortex Washing Machines

One of the biggest advantages of using a vortex fruit washer is its ability to clean fruits and vegetables thoroughly without causing damage. The swirling water flow reaches all sides of the produce, even in hard-to-clean areas like crevices, folds, or uneven surfaces. This ensures that dirt, sand, pesticide residues, and other contaminants are effectively removed, helping food processors meet strict hygiene standards.

Another important benefit is how gently the machine handles the produce. Unlike harsh brushing or high-pressure sprays, the vortex motion mimics the softness of hand washing. This makes it especially suitable for delicate items like leafy greens, berries, or tomatoes, which are prone to bruising or tearing during traditional washing methods.

In addition to improving cleanliness and reducing product damage, vortex washing machines also save a significant amount of labor. The automated process reduces the need for manual washing, sorting, and handling, which helps streamline production and reduce operating costs. Many machines also include features like automatic discharging and water recycling systems, further improving efficiency.

Water usage is another area where vortex machines excel. Compared to manual washing or older washing technologies, vortex washers are designed to use water more efficiently. With built-in filtration and sediment separation, many models allow for continuous reuse of water while maintaining cleanliness—an important factor in sustainable food processing.

Lastly, vortex washing machines contribute to a more hygienic working environment. Most are constructed from SUS304 food-grade stainless steel, which resists corrosion and is easy to clean. Some models also come with built-in ozone or UV sterilization systems, helping to eliminate bacteria and reduce the risk of cross-contamination during washing.

D. Common Applications

Industrial vortex fruit washers are used across a variety of food sectors, including fruit and vegetable processing plants, frozen produce factories, ready-to-eat salad producers, commercial central kitchens and catering units, canning and pickling lines and organic produce farms.

These machines are suitable for many types of produce: spinach, lettuce, cabbage, apples, carrots, berries, cucumbers, mushrooms, and more.

E. What to Look for When Choosing a Vortex Washer

●Capacity

Choose based on how many kilograms or tons per hour you need to wash.

●Produce Type

Delicate vs. hard, leafy vs. root vegetables.

●Material

SUS304 stainless steel is the industry standard for hygiene and durability.

●Added Features

Air bubbling, water recycling, auto-discharging, or ozone treatment.

●After-Sales Support

Reliable technical support and spare parts availability are crucial.

F. Vortex Washing Machine Manufacturers Comparison Table

| Manufacturer | Country | Strengths | Suitable For | Website |

| Sormac | Netherlands | High-quality build, hygienic design, strong R&D in leafy vegetable cleaning | Fresh-cut vegetable processors, salad producers | https://sormac.com/en-us |

| KRONEN GmbH | Germany | Advanced automation, air bubble systems, global service support | Medium to large food processing facilities | https://www.kronen.eu/en/ |

| Taibo Food Machine | China | Customizable features, cost-effective, durable SUS304 construction | Central kitchens, fruit & vegetable processors | https://cntaibo.com/ |

| M&T Engineering Equipments | Italy | Flexible designs, custom-built solutions, reliable cleaning performance | Small to industrial-scale fruit & vegetable plants | https://mandtprojects.com/index.html |

G. Vortex Washing Machines Comparison Table

| Feature / Brand | Sormac | KRONEN GmbH | Taibo Food Machine | M&T Engineering Equipments |

| Country of Origin | Netherlands | Germany | China | Italy |

| Machine Material | SUS304 stainless steel | SUS304 stainless steel | SUS304 stainless steel | SUS304 stainless steel |

| Cleaning Technology | Vortex water flow + optional air jets | Vortex flow + air bubble system | Vortex flow + optional air bubble | Vortex flow (customizable air bubble) |

| Filtration System | Yes, with sediment removal | Yes, with fine particle filters | Yes, optional multi-stage filters | Available on request |

| Ozone/UV Sterilization | Optional | Optional | Optional | Available on request |

| Capacity Range | Up to 3,000 kg/h | 500 – 3,000 kg/h | 300 – 2,500 kg/h (customizable) | Custom-designed per project |

| Automatic Discharge | Yes | Yes | Yes | Optional (custom-built) |

| Water Recycling | Yes | Yes | Yes | Optional |

| Best For | Leafy vegetables, salad mixes | All produce types, especially soft fruits | Wide range of fruits and vegetables | Root and hard vegetables, mixed produce |

| Customization Options | Limited | Moderate | High | Very high |

| After-Sales Support | Global network | Global network | Available globally | Europe-focused, responsive service |

Notes:

●Capacities and features vary by model—each manufacturer offers multiple configurations.

●Taibo and M&T are more flexible with custom designs and budget-friendly options.

●Sormac and KRONEN emphasize automation, hygiene, and smart controls, often for higher-end or large-scale food processors.

Read to know more about these industrial vortex fruit washer manufacturers and their washing machines: Best 4 Vortex Washing Machine Manufacturers Worldwide

H. Why Choose Taibo’s Industrial Vortex Washing Machine?

At Taibo Machine, we manufacture high-performance industrial vortex washing machines built with food-grade stainless steel and customizable features to suit different production needs. Our equipment has been widely used in fruit and vegetable processing plants around the world, helping businesses improve cleaning results, reduce water and labor costs, and comply with food safety regulations.

We offer custom washing tank sizes and configurations, integrated air bubble and filtration systems, easy maintenance and energy-efficient design, responsive technical support and international delivery.

Conclusion

An industrial vortex washing machine is a smart investment for any food processor aiming to improve product hygiene, reduce labor, and increase production efficiency. Its swirling water flow cleans produce more thoroughly and gently than conventional methods, helping businesses meet the growing demand for clean, safe, and fresh food.

Ready to upgrade your fruit and vegetable washing line?

Contact Taibo Machine today for expert advice, a customized quote, or to schedule a demo. Let us help you build a cleaner and more efficient food processing operation.

More to Read

●Best 7 Manufacturers of Small Farm Vegetable Washing Equipment

●Top 7 Industrial Vegetable Washer Manufacturers in the World

●Top 8 Industrial Food Dicing Equipment Manufacturers Worldwide

一个回复