Introduction

Beetroot processing is the process of transforming raw beetroots into various products for human consumption or industrial use. It is an important activity for the food industry, as it can enhance the nutritional, sensory, and functional properties of beetroots, as well as create new opportunities for product development and market expansion. At the forefront of beetroot processing stand industrial beetroot cutting machines – innovative tools poised to reshape the way we approach beetroot processing.

Dive into this comprehensive guide as we unravel the complexities of beetroot processing, shining a spotlight on the pivotal role played by beetroot cutting machines and other food cutting equipment. Grasping the advantages, decision-making criteria, challenges, and diverse types of beetroot cutting machines is crucial for optimizing productivity and ensuring top-tier product quality.

Embark with us on a journey through the intricacies of beetroot processing. Navigate the selection process for the ideal cutting machine for food tailored to your business, confront common challenges encountered in beetroot cutting, and arm yourself with insights that will elevate your beetroot processing capabilities.

Section 1: The Benefits of Using Beetroot Cutting Machines in Food Processing

In the fast-paced world of food manufacturing, efficiency and precision are the cornerstones of success. Beetroot cutting machines emerge as indispensable allies in this pursuit, offering a multitude of benefits that redefine the landscape of beetroot processing.

1.1 Enhanced Efficiency:

Beetroot cutting machines streamline the processing workflow, significantly reducing manual labor and operational time. With automated cutting precision, these machines handle large quantities of beetroot with speed and accuracy, ensuring a more efficient production cycle.

For instance, the Taibo industrial vegetable fruit slicing machine has a remarkable cutting capacity of 1.5 to 3 tons of vegetables and fruits per hour. This is far beyond the efficiency of any human workers.

1.2 Consistent Product Quality:

Precision cutting isn’t just about speed; it’s about consistency. Beetroot cutting machines and other cutting equipment for food are supposed to deliver uniform cuts, slices, or dices, maintaining a standardized product quality that meets the stringent demands of the food industry. This consistency not only enhances the visual appeal of the final product but also ensures a consistent taste experience for consumers.

I’ll also take TBQC slicing machine for example. When the machine is working, it’s blades rotate at high speed synchronously, thus ensuring the vegetables slices are of the same thickness.

1.3 Cost-Effectiveness:

Investing in industrial food cutting machines for beetroot, carrot, potato, cassava, etc. proves to be a cost-effective choice in the long run. By minimizing the need for manual labor, reducing waste through precise cutting, and optimizing overall production processes, these machines contribute to a more financially sustainable and competitive food manufacturing operation.

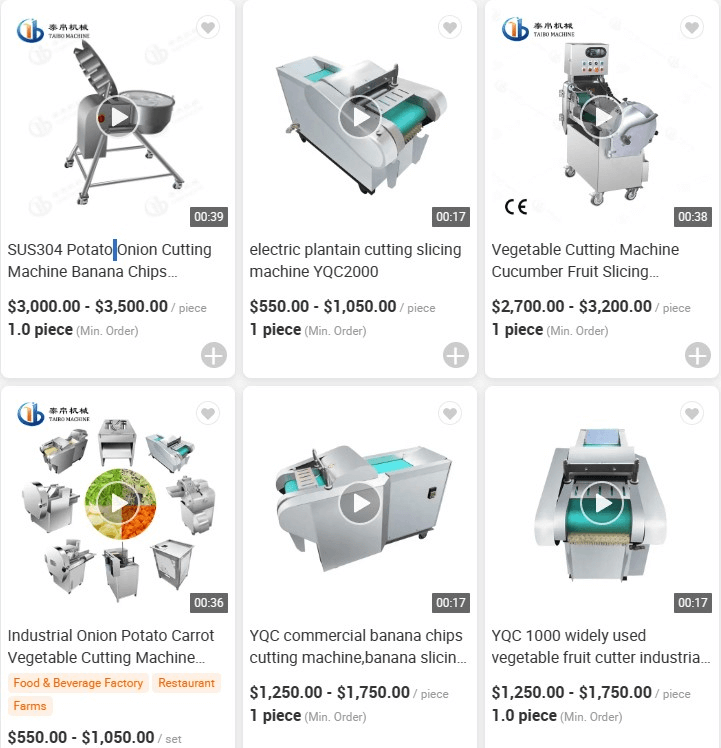

Below is the price of various fruits and vegetables cutting machines on a famous B2B website. The price ranges from 1000 USD to 4000 USD.

Using these machines can offer a higher return on investment than hiring human workers, as the minimum wage in New York City is 15.00 USD per hour. This is much higher than the average wage of agricultural workers in the United States, which was 13.99 USD per hour in 2020.

Therefore, investing in these machines can be more cost-effective and profitable than paying high wages to human workers.

1.4 Versatility in Processing:

Beetroot cutting machines are designed to adapt to various processing needs. Whether you require fine julienne cuts, thick slices, or custom shapes, these machines offer versatility in handling different cutting requirements. This adaptability makes them suitable for a wide range of culinary applications within the food manufacturing sector.

This two-head fresh cut processing machine is a versatile device that can handle various types of vegetables. It has two cutting heads that operate independently and can be adjusted according to the desired shape and size of the output. One cutting head is designed for slicing or sectioning vegetables that are placed on the conveyor belt, such as celery, leek, spinach, green onion, cucumber, and carrot. The other cutting head is equipped with a cutter disc that can produce shreds, slices, or cubes of vegetables that are fed into a separate inlet, such as melon and potato.

This machine is ideal for processing stem and leaf vegetables, as well as root and fruit vegetables, with high efficiency and precision.

1.5 Improved Hygiene and Safety:

Maintaining hygiene standards is paramount in the food industry. Beetroot cutting machines, with its structure completely made of high quality SUS304 stainless steel, contribute to a cleaner and safer processing environment. Reduced human contact with the product also minimizes the risk of contamination, ensuring the production of safe and high-quality food products.

In embracing beetroot cutting machines, food manufacturers and fresh cut vegetables and fruits processing industry not only optimize their operational processes but also elevate the overall quality and safety of their products. The integration of these advanced technologies marks a significant stride toward a future where efficiency and excellence harmonize in the realm of beetroot processing.

Section 2: Choosing the Right Beetroot Cutting Machine for Your Food Manufacturing Business

Selecting the most suitable industrial food cutting machine is a pivotal decision that can significantly impact the efficiency and output of your food manufacturing business. In this section, we’ll guide you through essential considerations to ensure you make an informed choice tailored to your specific needs.

2.1 Production Capacity:

Begin by evaluating the production capacity required for your business. Consider factors such as the volume of beetroot processed daily and peak production periods. Choosing a machine with an appropriate capacity ensures that your processing line operates smoothly without bottlenecks.

2.2 Cutting Mechanism and Options:

Different beetroot cutting machines offer various cutting mechanisms and options. Whether you need slices, dices, cubes, julienne cuts, or custom shapes, assess the machine’s capabilities to meet your specific product requirements. Some machines may come with interchangeable blades to enhance flexibility in processing.

For example, this vegetable and food dicing equipment is equipped with multiple sets of blades that can be customized to produce different sizes of diced materials.

Source: https://cntaibo.com/product/chd100-vegetable-and-fruit-dicing-machine/

2.3 Footprint and Space Considerations:

Evaluate the available space in your food processing facility. Beetroot cutting machines and fruits apples cutting machines come in various sizes, and it’s crucial to choose one that fits seamlessly into your layout. Optimize your space by selecting a machine that balances functionality with the available footprint.

2.4 Ease of Maintenance:

Regular maintenance is essential to keep your beetroot cutting machine operating at peak performance. Consider machines with user-friendly designs that facilitate easy cleaning and maintenance. Accessible components and straightforward maintenance procedures contribute to the longevity of the machine.

2.5 Compatibility with Existing Systems:

Ensure that the chosen beetroot cutting machine integrates seamlessly with your existing food processing systems. Compatibility is vital for a smooth workflow and prevents potential issues that may arise from mismatched equipment.

By carefully weighing these considerations, you can confidently choose a beetroot cutting machine that aligns with your production goals, enhances operational efficiency, and contributes to the overall success of your food manufacturing business.

Section 3: Common Challenges in Beetroot Cutting and How Machines Solve Them

Beetroot processing, while essential in the food manufacturing industry, is not without its challenges. In this section, we’ll explore the common hurdles faced in beetroot cutting and how the integration of cutting-edge machines provides effective solutions.

3.1 Irregular Shapes and Sizes:

Challenge: Root vegetables like potato, cassava, carrot, and beetroot always have irregular shapes, which can pose difficulties in achieving consistent cuts manually, leading to variations in product presentation.

Solution: Cutting machines for food industry employ precision cutting mechanisms that overcome the irregularities in shape, delivering uniform slices, dices, or cuts with meticulous accuracy.

3.2 Time-Consuming Manual Labor:

Challenge: Manual cutting of large volumes of beetroot is time-consuming and labor-intensive, affecting overall production efficiency.

Solution: Beetroot fruit cutting machines automate the cutting process, significantly reducing the need for manual labor and expediting the entire processing timeline.

3.3 Productivity Fluctuations:

Challenge: Peaks in production demand may lead to fluctuations in productivity, challenging manual processing capabilities.

Solution: Automated vegetable cutting equipment maintains consistent productivity levels, ensuring efficiency during both regular processing and peak demand periods.

3.4 Waste Generation:

Challenge: Inaccurate manual cutting often results in increased waste, impacting resource utilization and production costs.

Solution: Industrial beetroot fruit cutting machines minimize waste by precisely cutting each beetroot, optimizing the use of raw materials and contributing to cost-effective production.

3.5 Hygiene Concerns:

Challenge: Manual handling increases the risk of contamination, raising concerns about product hygiene and safety.

Solution: Beetroot cutting machines, with their enclosed and automated processes, enhance hygiene by minimizing human contact with the product, ensuring a safer processing environment.

3.6 Worker Fatigue and Safety:

Challenge: Prolonged manual cutting can lead to worker fatigue, impacting both productivity and safety.

Solution: Beetroot cutting machines reduce reliance on manual labor, promoting a safer working environment and mitigating the risk of injuries associated with repetitive tasks.

By addressing these common challenges, cutting machines for food, vegetable and fruit not only streamline the processing workflow but also contribute to higher-quality products, increased operational efficiency, and a safer working environment for your food manufacturing business.

Conclusion

Mastering beetroot processing through the integration of cutting machines is undoubtedly a transformative step for any food manufacturing business. As explored in this comprehensive guide, the benefits of employing beetroot cutting machines are far-reaching.

In adopting beetroot cutting machines, food manufacturers not only overcome these challenges but also pave the way for increased efficiency, reduced costs, and a safer working environment.

More to Read

●Mastering Efficiency: Unveiling the Secret of Industrial Vegetable Drying Equipment

●Best 6 Meat Processing Equipment Suppliers in India