Introduction

When it comes to efficient and high-quality meat processing, the right equipment can make all the difference. Whether you’re producing sausages, meatballs, or other stuffed meat products, a reliable meat stuffing mixer is essential.

In this blog, we’ll explore some of the top manufacturers in the industry, focusing on their advanced meat stuffing mixers and highlighting the features and benefits that make these machines indispensable in modern meat processing.

1. Taibo Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Industrial meat processing equipment, pork processing equipment, vegetables peeler machine, fruit wash machine, industrial food cutting machine, dough divider rounder, vegetable chopping machine, garlic separator machine, beetroot slicer, meat stuffing mixer.

About the Company:

Taibo Food Machine is a leading manufacturer specializing in advanced food processing equipment, especially meat processing equipment, catering to the global food industry.

With a strong commitment to innovation and quality, Taibo provides a wide range of solutions designed to meet the demands of modern meat processing. From cutting and grinding to mixing and forming, their equipment is engineered for efficiency, precision, and reliability, ensuring optimal performance in every application.

The company’s dedication to technological advancement and customer satisfaction drives them to continuously improve their offerings, providing equipment that not only enhances productivity but also ensures the highest quality end products. Whether for large-scale industrial operations or smaller processing facilities, Taibo’s meat processing equipment is built to deliver excellence in every stage of production.

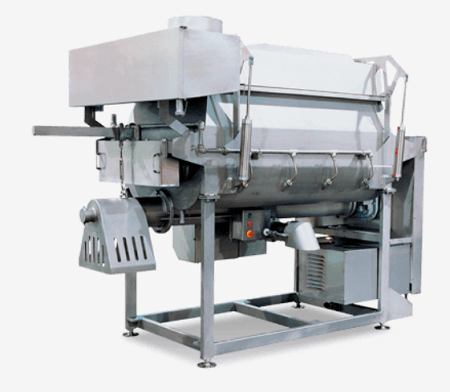

About the Taibo Meat Stuffing Mixer:

The Taibo Machine two-shaft meat stuffing mixing machine is designed to deliver exceptional performance in meat processing. Engineered for efficiency, this mixer features a dual-shaft design that ensures thorough and consistent mixing of meat and other ingredients. The counter-rotating shafts provide a balanced and even blend, while the gentle mixing action preserves the texture and quality of the product.

Click to know more

Ideal for meat stuffing and various other meat preparations, this machine is built to handle high-capacity production with ease. Its robust construction ensures long-lasting durability, even in demanding environments. The user-friendly design allows for easy operation and maintenance, making it a reliable choice for processors seeking to optimize their production processes.

2. Risco

Location: Via della Statistica, 2 – PO Box 130 – 36016 Thiene (VI)

Company Type: Manufacturer

Year Founded: 1968

Main Products:

●Vacuum fillers, sausage systems, minced meat systems, forming systems, grinders, flakers, mixers, tying machine.

About the Company:

Risco is a prominent global leader in the production of machines and systems for meat processing. With over fifty years of experience, the company has solidified its position in international markets, blending deep-rooted family traditions with cutting-edge management practices. This unique combination has enabled Risco to pioneer innovative solutions, processes, and markets, ensuring sustained growth and success.

The company’s philosophy centers around adaptability and customer-focused innovation, which is evident in each Risco product. Embracing modernity, Risco continually advances its technology and operations, ensuring that its products and services meet the highest standards.

About the Risco Meat Stuffing Discharge Mixer:

The Risco RS 1500 is a high-capacity frontal discharge mixer designed for large-scale food industry applications. With a 1500-liter bowl, it is engineered to handle significant volumes of products with precision and care.

The mixer features Risco’s innovative intersecting mixing paddle system, which ensures gentle movement of the product without applying excessive pressure in critical areas of the bowl. This design makes it ideal for processing a wide range of products, including meat, confectionery, liquids, fruits, and vegetables.

The RS 1500 guarantees nearly 100% uniform distribution in a short time, making it highly efficient. It also comes equipped with a modern Risco microprocessor, allowing for automatic working programs and the auto-reverse function of the mixing paddles.

3. Handtmann

Location: 28690 N. Ballard Drive, Lake Forest, IL 60045

Company Type: Manufacturer

Year Founded: 1873

Main Products:

●Grinding systems, mixing systems, emulsifying systems, vacuum filling machine, forming machine, dough dividing and cutting machine, depositing and filling machine, co-extrusion system, tying and link cutting, clipping and declipping system.

About the Company:

Handtmann is a globally renowned company, recognized for its advanced technology, innovation, and focus on individuals. Rooted in the Swabian town of Biberach, the company has been shaped by five generations of the Handtmann family, who have seamlessly blended modernity with tradition.

The Handtmann Group of Companies is strategically organized into six divisions, each operating autonomously with decentralized management structures. This approach ensures that the company remains agile, customer-focused, and responsive to employee needs. The company’s dynamic and authentic approach continues to drive its global success, reflecting a deep commitment to technological excellence and social responsibility.

About the Handtmann 2-Shaft Meat Stuffing Mixer:

The Handtmann 2-shaft mixer is engineered for thorough and efficient mixing of a wide range of products, from viscous to highly viscous substances. Ideal for food and pet food production, it excels in processing diverse items such as meat, vegetables, fruits, dairy, baby food, confectionery, and even non-food products. Whether integrated into a production line or used as a stand-alone machine, this mixer delivers fast and homogeneous results, tailored to specific applications through its adaptable mixing technology.

Key advantages include high economic efficiency, production reliability, and user-friendly operation. The system’s compact, closed design ensures excellent hygiene and short mixing times, while the intuitive process control interface allows for easy monitoring and adjustment.

4. Provisur

Location: 222 North LaSalle Street, Suite 720, Chicago, IL 60601, United States

Company Type: Manufacturer

Year Founded: 2008

Main Products:

●Industrial defrosting equipment, commercial marinating tenderizing and injecting equipment, Weiler commercial food grinder and mixers, separation equipment, Formax food forming equipment, frying cooking and smoking equipment, meat sizing equipment, slicing equipment, freezing equipment.

About the Company:

Provisur has been at the forefront of innovation in the industrial food processing industry for over 50 years. Headquartered in Chicago, Illinois, the company is renowned for its extensive portfolio of trusted, high-performing brands, including Weiler®, Formax®, and Hoegger®. With over 350 global patents, Provisur’s revolutionary designs are used worldwide, making the company a leader in delivering cutting-edge solutions.

The company’s legacy brands and diverse product applications span ground, formed, and portioned products, sliced products like bacon, whole muscle products, protein alternatives, and more.

Provisur’s global network of sales and service locations ensures that customers receive local support, helping them achieve higher performance, advanced hygiene, and labor-saving automation.

About the Weiler Meat Mixer:

The Weiler® mixers are designed to enhance productivity and product quality across a broad range of food processing applications. Featuring a unique twin overlapping paddle system combined with a full-length unload screw, these mixers provide quick, thorough mixing that is gentle on your product while ensuring a consistent blend of all raw materials.

Ideal for ground, formed, portioned, sliced, and whole muscle products, as well as mechanically separated items, bone-in products, sausages, protein alternatives, and pet food, Weiler® Mixers deliver the highest quality end product.

Engineered for durability in demanding environments, these mixers are available in various models to suit different production needs. The low paddle RPM is gentle on the product, ensuring consistent quality, while the polished contact surfaces minimize fat separation, reduce waste, and increase yields.

Conclusion

In the competitive world of meat processing, investing in the right equipment is key to ensuring product quality and operational efficiency. By choosing the right mixer, processors can achieve consistent, high-quality results while optimizing their production processes.

Whether you’re looking for durability, innovation, or versatility, the industry leaders in this blog have the solutions to help you succeed.

If you’re ready to enhance your meat processing operations, explore Taibo Machine’s range of meat stuffing mixers today. Visit our website or contact us for more information and find the perfect solution for your production needs!

More to Read

●Top Garlic Separator Manufacturers: Enhancing Efficiency in Garlic Processing

●Maximizing Efficiency with the Right Industrial Garlic Separator: A Comprehensive Overview

●The Ultimate Guide to Industrial Vacuum Food Tumblers in Food Processing

●The Essential Guide to Industrial Frozen Meat Processing Equipment

3 回复