Introduction

When it comes to producing high-quality sausages, an efficient and reliable sausage mixer machine is essential for achieving the perfect blend of meat, fat, spices, and seasonings. Sausage mixer machines are crucial in ensuring consistent texture, taste, and product integrity—making them indispensable in both small-scale butcher shops and large-scale food processing factories.

In this blog, we explore some of the top manufacturers of sausage mixer machines from around the world. Whether you are looking for a machine that offers versatility, durability, easy cleaning, or cutting-edge features like vacuum mixing or programmable controls, this guide will help you discover reputable brands and factories worth considering.

1. INDUSTRIAL FUERPLA S.L.

Location: Avenida del camino nou 12 , 46910 – Bentusser – Valencia – Spain

Company Type: Manufacturer

Year Founded: 1971

Main Products:

●Kneader mixer, vacuum mixer, vacuum mixer, stuffer, filling machine, portioner, automatic doble clipper, meat mincers, meat grinders, automatic electric boilers.

About the Company:

Founded in 1971, INDUSTRIAL FUERPLA S.L. has been dedicated to manufacturing high-quality machinery for the meat and sausage industry. Building on decades of expertise, the company has expanded its product offerings to serve a wide range of food sectors, including croquettes, meatballs, salads, pet food, cheese, omelettes, fish, and vegetables.

Recognized twice with the Export Award from the Valencia Chamber of Commerce, Fuerpla proudly exports its machinery to customers across five continents through a strong global distributor network. The company remains committed to delivering reliable, high-performance equipment and tailored technological solutions that keep pace with the evolving demands of the international food processing market.

About the Fuerpla Vacuum Mixer:

Designed for efficiency, durability, and precision, this 350-liter vacuum mixer is an ideal solution for processing a wide range of food products. Built with a double-jacketed mixing bowl, it offers optional heating or cooling functions to suit various recipe and production needs.

Featuring a robust ZZ-type double parallel arm kneading system with bi-directional rotation, the mixer ensures a gentle yet thorough blending of ingredients, preserving product quality while achieving a perfectly homogeneous mix. The dual-speed blades rotate independently to enhance mixing performance even further.

For ease of operation, the mixer includes a 200-liter standard forklift arm lift for quick and safe loading, as well as a tiltable tank that simplifies both product discharge and cleaning.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Centrifugal fried food deoiling machine, meat processing equipment, food processing lines, dough processing machine, industrial vegetable washer, industrial dicer machine, food peeling machine, etc.

About the Company:

Taibo Machine is a trusted manufacturer specializing in the design, production, and supply of high-quality food processing equipment. The company serves a global market with innovative solutions that meet the diverse needs of food manufacturers across various industries, including meat, vegetables, snacks, bakery, and ready-to-eat products.

With a focus on reliability, efficiency, and user-friendly operation, Taibo offers a wide range of machines such as vegetable washing machines, frying equipment, dough processing machines, meat processing equipment, and food drying machines.

About the Taibo Sausage Mixer Machine:

Taibo meat stuffing and fillings mixing machine is specially designed to deliver efficient, thorough, and uniform mixing of various ingredients such as minced meat, vegetables, starches, seasonings, and other fillings.

(Click to know more)

Equipped with a double-shaft mixing system and sloped paddles, the machine ensures that all ingredients are evenly blended without creating air pockets, which is crucial for maintaining the right texture and consistency in products like sausages, dumplings, meatballs, patties, and other stuffed food items.

This mixer stands out for its excellent mixing performance. The two shafts rotate in both forward and reverse directions, ensuring complete and balanced mixing while gently kneading the meat mixture. This action promotes effective protein extraction and air removal, resulting in a firm and elastic final product with improved texture and appearance.

3. Jarvis India

Location: Plot 93A, Sector 5 – IMT Manesar, Gurgaon, Haryana 122050, INDIA

Company Type: Manufacturer

Year Founded: 2008

Main Products:

●Vegetable chopper and cutter, peeler and cleaners, deep fat fryer, planetary mixer, spiral dough mixer, vegetable washer, meat mixer, brine injector tenderiser, meat slicer, sausage stuffer.

About the Company:

Jarvis India, a wholly owned subsidiary of Jarvis Products Corporation (USA), serves as the dedicated sales and service center for customers across India and neighboring countries. Located in the Delhi NCR region, Jarvis India offers comprehensive support with a full inventory of spare parts, blades, and accessories for Jarvis machinery, ensuring smooth and uninterrupted operations for its clients.

Backed by a team of experienced technical specialists, Jarvis India provides on-site guidance, training, and advice on best practices and the latest innovations to help food processors improve efficiency, safety, and productivity. In addition to Jarvis’s renowned meat and poultry processing equipment, the India office supplies a wide range of world-class tools.

About the Jarvis India Meat Mixer:

Jarvis India offers a comprehensive range of high-performance meat mixers designed to meet the diverse needs of meat processors, supermarkets, hypermarkets, hotels, and catering services. Available in various sizes, these mixers ensure reliable, uniform mixing of meat, spices, and other ingredients—perfect for producing sausages, hamburgers, meatloaf, and more.

Built for intensive use, the mixers come in both single- and double-paddle models. The paddles rotate in dual directions—mixing ingredients in one direction and kneading in the other—eliminating air pockets for consistent texture, which is especially important for dry-cured sausage production. The mixers can process both small and fully loaded batches with high liquid absorption capacity, and can even function as massaging or marinating machines when the breaker bars are removed.

4. ANKO FOOD MACHINE CO., LTD.

Location: No.351, Sec. 1, Zhongzheng Rd., Sanxia Dist., New Taipei City 237, Taiwan, China.

Company Type: Manufacturer

Year Founded: 1978

Main Products:

●Tortilla production line, empanada making machine, high speed dicing machine, conveyor fryer, seasoning mixer, stir fryer, automatic meatball and fish ball making machine, etc.

About the Company:

ANKO is dedicated to providing complete food production solutions that help customers succeed in the food industry. Through customized planning and versatile production lines, the company works together with their clients to create new market opportunities and drive business growth.

To ensure consistent machine quality, ANKO earned ISO 9001 certification in 1999. Their equipment complies with international food sanitation and electrical safety standards such as CE and UL, making it easy to pass various regulatory inspections. ANKO has become a leading brand in the global market for Chinese food-making machinery by offering product customization, competitive pricing, recipe consulting, full turnkey services, and reliable after-sales support. With 47 years of experience and customers in more than 114 countries, ANKO is a trusted partner for creating delicious business opportunities.

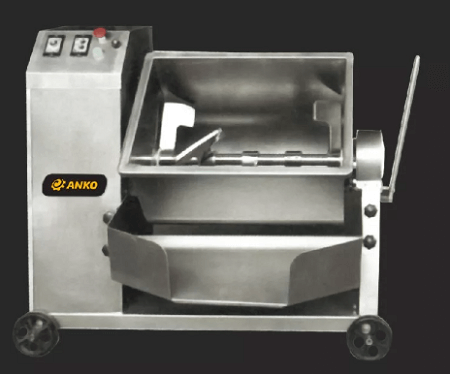

About the Anko Seasoning Mixer:

Seasoning and mixing large volumes of ingredients—such as fillings, sausage meat, or sticky rice—can be a labor-intensive and time-consuming task for many food manufacturers. The Anko seasoning mixer offers a smart and efficient solution by thoroughly blending powdered, liquid, and solid flavorings with ease. Simply load all ingredients into the hopper, and the machine takes care of the rest.

Equipped with a stirring bar featuring dual-directional blades, the mixer ensures an even and complete mix every time. Both mixing speed and duration can be adjusted to meet specific production requirements. The easy-to-use unloading mechanism simplifies the removal of mixed materials, further enhancing production efficiency.

Conclusion

Choosing the right sausage mixer machine is an important decision that can directly impact product quality, production efficiency, and operational costs. Whether your focus is on small-batch specialty sausages or high-volume commercial production, these companies mentioned provide machines with reliable performance, user-friendly designs, and compliance with international food safety standards.

If you are looking for the ideal sausage mixer machine to upgrade your production line, don’t hesitate to contact Taibo Machine for quote. The right solution for your business is just a click away!

More to Read

●Top 4 Frozen Meat Block Flaker Manufacturers Worldwide

●Top 4 Industrial Frying Machine Manufacturers in Europe

●The Ultimate Guide to Choose the Right Industrial Meat Stuffing Mixer

2 回复