I. Introduction

Fruit processing lines are an essential part of the food industry, as they enable the efficient and consistent processing of various types of fruits for different applications. From fresh fruits to frozen, canned, and dried dehydrated fruits, processing lines are necessary for creating a wide range of products such as juices, jams, concentrates, and more.

In this article, I’ll provide an overview of fruit processing lines and their components, as well as the benefits they offer to the food industry. I’ll also discuss factors to consider when choosing fruit processing lines, maintenance and troubleshooting procedures, and the importance of proper training and documentation.

II. Types of Fruit Processing Lines

Fruit processing lines can be categorized based on the type of fruit they process and the type of finished products. Some of the most common types of fruit processing lines include:

Fresh Fruit Processing Lines

Fresh fruit processing lines are used for fruits that are harvested ripe and are meant to be consumed or further processed as soon as possible. The processing typically involves cleaning, sorting, grading, and packaging of fruits.

●Vegetable Fruit Washing Waxing Weight Grading Lines

This production line is designed for washing, waxing, drying, weighing, and grading fruits and vegetables such as potatoes, oranges, avocados, apples, and peaches. The line consists of a washing machine, a conveyor and manual sorting machine, a lifting machine, a waxing and drying machine, and a weight grading machine. The layout and weight ranges can be customized according to the client’s needs and factory structure.

The production process involves bubble washing, brush washing, drying and waxing, wax film drying, and weight grading.

●Vegetable Fruit Washing Waxing Drying Size/Diameter Grading Lines

This production line is designed for cleaning, waxing, drying, and size grading fruits and vegetables such as taro, potatoes, onions, oranges, and lemons. The line consists of a large water tank bubble cleaning machine, a brush spraying cleaning machine, a waxing machine, a drying machine, a sorting table, a lifting machine, and a size grading machine. The production line can be customized according to the client’s required output and size ranges.

The production process involves bubble cleaning, brush spraying cleaning, drying and waxing, wax film drying, and size grading.

Frozen Fruit Processing Lines

Frozen fruit processing lines are used for fruits that are processed and frozen to preserve their flavor and nutrients and extend their shelf life. The processing typically involves cleaning, sorting, peeling, cutting, blanching, freezing, and packaging of fruits.

These lines are essential in the production of frozen fruits and are used to create a variety of products, such as frozen berries, frozen mango, frozen peaches, fruit purees, and fruit juices.

Canned Fruit Processing Lines

Canned fruit processing lines are used for fruits that are processed and canned in a syrup, juice solution or other liquid to preserve their flavor and nutrients. These lines are designed to handle a variety of fruits, including peaches, pears, pineapples, and cherries.

The processing typically involves cleaning, sorting, peeling, coring, slicing, and blanching the fruits before packing them into cans.

Dried Fruit Processing Lines

Dried fruit processing lines are used for fruits that are dried to remove their moisture, extend their shelf life and enhance the texture and taste. The processing typically involves cleaning, sorting, cutting, blanching, then removing the moisture through a series of drying stages and last packaging dehydrated fruits.

Dried fruit processing lines are used to produce a range of dried fruits, including raisins, apricots, figs, and dates. Cutting fruits into thin slices, you get crispy fruit chips like apple chips and so on. The final product can be packaged for sale or used in other food products, such as cereals or trail mixes.

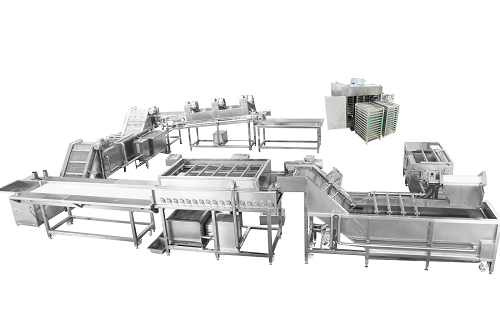

A cutting-edge food processing lines for fruit can handle a wide range of materials such as apple, kiwi, pineapple, cassava, potatoes, onions, oranges, lemons and more.

The process begins with a brush-roller washing and peeling machine that ensures all dirt and debris is removed from the produce. Next, the bubble washing machine uses gentle yet effective cleaning techniques to get the produce squeaky clean.

For a more thorough wash, the brush-roller high-pressure spray washing machine is used to blast away any remaining dirt or grime. Once the produce is clean, an elevator is used to transport it to the air-drying machine, which removes any excess water from the surfaces.

Finally, the cutting machine makes quick work of the produce, ensuring that it is ready for use in a variety of recipes. And with the added convenience of a hot air circulation drying machine, you can easily dehydrate the produce to preserve it for future use.

Whether you’re a small operation or a larger factory, this production line can be customized to suit your needs.

III. Components of Fruit Processing Lines

Fruit processing lines consist of various equipment and machinery that work together to process fruits into different products.

These equipment and machinery can be classified into different categories based on their functions, which include cleaning and washing, sorting and grading, cutting and slicing, drying and dehydrating, grinding and pulping, pressing and extracting, heating and pasteurization, and packaging equipment.

Cleaning and Washing Equipment

Cleaning and washing equipment is used to remove foreign materials, dirt, and debris from fruits before processing. According to the working principle, food washing machines can be categorized into bubble washing machines and vortex washing machines.

Drying and Dehydrating Equipment

Dryers are used to remove excess moisture on the surface of fruits after washing or inside the fruits. Most commonly seen drying machines for vegetables and fruits are hot air circulation drying machines, continuous fan drying machines and centrifugal water removing machines.

Cutting and Slicing Equipment

Cutting and slicing equipment is used to cut and slice fruits into smaller pieces for further processing. These equipment includes cutters, slicers, dicers and choppers. With automatic food cutting machines, you can cut tons of materials into specific shapes and sizes effectively.

Grinding and Pulping Equipment

Grinding and pulping equipment is used to grind fruits into a pulp, which can be further processed into various products such as juices, purees, and concentrates. These machines include grinders, pulpers, and blenders, which can be adjusted to achieve the desired texture and consistency of the final product.

Grinders are used to grind fruits into a fine pulp, while pulpers are used to remove seeds and skins from the pulp.

Pressing and Extracting Equipment

Pressing and extracting equipment is used to extract juice from the pulp, which can be used to make different products such as nectars, concentrates, and syrups.

These machines include presses, extractors, and filters. Presses are used to extract juice from the pulp by applying pressure, while extractors are used to extract juice by spinning the pulp in a centrifuge. Filters are used to remove any impurities from the extracted juice.

Heating and Pasteurization Equipment

Heating and pasteurization equipment is used to heat and pasteurize the extracted juice to destroy any harmful microorganisms and extend the shelf life of the product.

These equipment include heaters, pasteurizers, and sterilizers. Heaters are used to heat the juice to a specific temperature, while pasteurizers and sterilizers are used to pasteurize and sterilize the juice, respectively.

Packing Equipment

Packaging equipment is used to package the processed products into different containers such as bottles, cans, and pouches. These equipment include fillers, sealers, and labelers. Fillers are used to fill the containers with the processed products, while sealers are used to seal the containers. Labelers are used to label the containers with product information such as the name, ingredients, and nutritional value.

IV. Benefits of Fruit Processing Lines

Fruit processing lines offer a range of benefits for businesses in the food industry. Some of the key benefits include:

Improved Product Quality and Consistency

Food processing lines for fruit allow for greater control over the production process, resulting in a more consistent and higher-quality final product, making sure the products are free from contaminants. The processing also helps to maintain the nutritional value, flavor, and appearance of the fruits.

The machinery used in these lines can be adjusted to achieve the desired texture, flavor, and appearance of the fruit product, ensuring that it meets customer expectations.

Increased Efficiency and Productivity

Fruit processing lines can process large quantities of fruits in a short amount of time, which can increase productivity and reduce production costs. They are designed to streamline the production process, reducing the time and labor required to process fruits manually. This leads to increased efficiency and productivity, allowing businesses to produce more fruit products in less time.

Reduced Waste and Costs

Fruit processing lines can reduce waste by utilizing all parts of the fruit, including the pulp and juice, which can be used to make different products. This can also reduce production costs by minimizing waste and maximizing yield. They can help to reduce waste and costs associated with the production process. The machinery used in these lines is designed to maximize the yield of usable fruit product, minimizing the amount of waste generated.

Extended Shelf Life

Fruit processing lines can extend the shelf life of processed products by using pasteurization and sterilization techniques to destroy harmful microorganisms and prevent spoilage.

Speaking of extending shelf life, the waxing fruit is also a common practice in the food industry. Coating the surface of fruits with a thin layer of wax protects them from moisture loss, spoilage, and damage during transportation and storage. Waxing can extend the shelf life of fruits by inhibiting the growth of bacteria and fungi that can cause spoilage. What’s more, waxing can improve the transportability of fruits by making them more resistant to damage during long-distance transportation.

V. 4 Factors to Consider When Choosing Fruit Processing Lines

When choosing a fruit processing line, it is important to consider several factors that will affect the final product and the overall efficiency of the process. Some of the key factors to consider are:

Type of Fruit to be Processed

Different fruits require different processing techniques and equipment. It is important to choose equipment that is suitable for the type of fruit being processed.

Production Capacity

The production capacity of a fruit processing line is one of the most important factors to consider. It determines the amount of fruit that can be processed per unit of time. The capacity required will depend on the size of the operation and the demand for the product. It is important to choose a fruit processing line that can handle the required volume of fruit and meet the production targets.

By the way, a qualified manufacturer should be able to design the production lines according to your specific requirements like capacity, layout, factory size, etc. If they can’t, just find another one.

Processing Requirements and Parameters

Different fruits have different processing requirements and parameters. It is important to choose a fruit processing line that is designed to process the specific type of fruit being processed. This includes considerations such as the size and shape of the fruit, the desired texture of the final product, and the processing temperature and time.

Budget and Space Constraints

Budget and space constraints are also important factors to consider when choosing a fruit processing line. The cost of the equipment and installation should be within the budget of the operation. The space available for the equipment should also be considered, as larger equipment may require more space.

VI. Maintenance and Troubleshooting of Fruit Processing Lines

Regular cleaning and maintenance procedures are essential for keeping a fruit processing line operating efficiently. Maintenance procedures should be performed on a regular schedule to ensure that the equipment is working properly and that any issues are addressed promptly. Common issues that may arise include equipment breakdowns, clogs, and leaks.

It is important to have a trained maintenance team in place to perform regular maintenance and troubleshoot any issues that arise. Proper documentation of maintenance procedures and issues should also be maintained to track the performance of the equipment and identify any recurring problems.

VII. Conclusion

In conclusion, fruit processing lines are essential for the food industry, as they allow for the efficient processing of fruit into a variety of products. The different types of fruit processing lines and components discussed in this article provide an overview of the various options available to processors.

When choosing a fruit processing line, it is important to consider factors such as production capacity, processing requirements and parameters, budget and space constraints, and maintenance and troubleshooting procedures. By carefully considering these factors and selecting a fruit processing line that meets the needs of the operation, processors can improve product quality and consistency, increase efficiency and productivity, reduce waste and costs, and extend the shelf life of their products.

I hope this article has been helpful in providing an overview of fruit processing lines and the factors to consider when selecting one. If you would like to learn more about our fruit processing lines and how they can benefit your operation, please contact us today.

If you are looking for more about the vegetable fruit processing equipment, please click to read.

●8 Factors Help You Choose Quality Food Washing Equipment

●List of Global Food and Food Processing Exhibitions 2023

●Best 7 Manufacturers of Small Farm Vegetable Washing Equipment