Food washing is a crucial process in the ever-evolving world of food processing. Depending on the technology and equipment used, it can either hinder or help food manufacturers. If you’d like to identify high-quality food vegetable fruit washing equipment, take the following 8 factors into consideration.

①Quality and Durability

In any purchasing decisions that’ll be made, quality should always come first. Investing in the most robust equipment you can afford will save you money in the long term and minimize the risk of breakdowns during use.

But how can you tell if the machine is durable without seeing and inspecting it in person?

It’s quite simple. Just make sure the manufacturer uses quality raw materials and components.

Raw Material

The two bubble vegetable washing machine shown in the picture below may look quite the same. However, the service life of the first one is nearly 4 times longer than the second one. Thus, the price is also higher.

The difference is: the first is completely made of SUS304 stainless steel, including the shell, frame, conveyor mesh belt, while the second is made of 201 or 202 stainless steel, or partly made of 304 stainless steel.

The nickel content in 201 stainless steel is lower than that in 304 stainless steel, while the content of manganese and nitrogen is higher. Therefore, 201 stainless steel is cheaper than 304 stainless steel, but it is also more prone to corrosion, especially in humid environments like vegetable fruit processing factories, food processing factories, etc.

201 Stainless steel is generally suitable for dry environments, such as in the decoration industry, industrial products, and other low-end products. On the other hand, 304 stainless steel has better corrosion resistance, applicable to industries such as food processing and medicine. It is also suitable for coastal or humid areas.

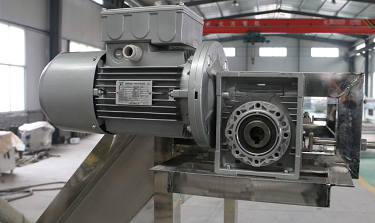

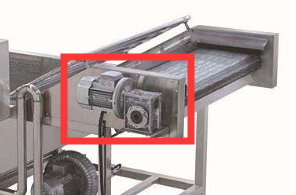

Component

In terms of components, the first uses Branded ZIK variable frequency gearmotor with high durability and stability. You can adjust the speed of the washing equipment according to your real working situation. However, the second uses average gearmotor, which is unstable and easily burnt. In addition, it is hard to adjust the speed.

Every little detail contributes to huge differences in quality and durability of the food washing equipment. To assess a machine’s quality, it’s also advisable to read reviews and seek advice from a dealer or supplier.

②Washing Performance

In my opinion, the washing performance depends on the design and structure. A quality food washing equipment is capable of cleaning various vegetables, fruits, meat, seafood and other foods thoroughly, removing the dirt, grass, hair, bugs and other impurities to the greatest extent.

This requires the equipment to have effective impurity removal and filtration system.

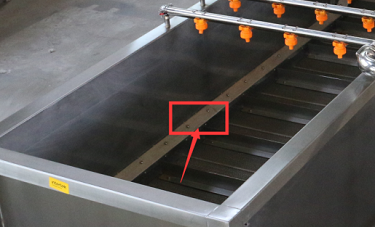

Design

The first washing equipment for food vegetables fruits features overflow outlet and arc-shaped impurity removal system. Residues floating on the surface will be filtered, while the second doesn’t have system like this. Impurities and residues will stay in the machine, contaminating materials.

Structure

The first machine has independent water circulation tank, which can effectively remove impurities. However, some vegetable fruit food washing machines have a very small circulation tank. Plus, the tank is integrated with the machine. Some don’t even have circulation tanks, leading to poor impurity removing and filtration performance.

③Water Consumption

Water consumption is another important consideration when choosing food washing machines. A high-quality machine should be able to reduce water consumption while maintaining excellent washing performance. This is not only environmentally friendly but also helps to reduce operating costs.

The amount of water used by a food washing equipment can vary greatly depending on its design.

Efficient water usage is achieved by using a closed-loop water filtration and circulation system, which recycles the water used during washing. The first machine shown in the picture uses filter screen and filter tanks as water circulation system, which ensures impurities will not flow back to the washing tank, contaminating the water. This will greatly reduce the frequency of replacing water, thus decreasing the water consumption by up to 60% compared to traditional washing methods. In the meantime, it ensures that the food is washed with clean water. This helps to prevent contamination and ensure food safety

In contrast, the second machine may require more water due to its lack of a closed-loop water filtration and circulation system.

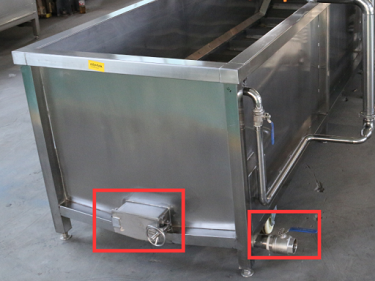

④Impurity Discharge and Management

One of the primary objectives of lean manufacturing is to minimize the labor involved in processing. If impurities during washing cannot be discharged completely, this will slow down the production and result in contaminated products. To mitigate this issue, I recommend utilizing food washing machines with large and separate impurities discharging outlets.

The first machine has two separate outlets, one for impurities and one for water. The second machine only has one water outlet, leading to the accumulation of impurities in the washing tanks and affecting the washing performance. Moreover, it costs extra time and labor to clean the impurities.

A quality machine should have a system that manages and disposes of impurities effectively. This not only ensures that the machine operates at maximum efficiency but also reduces the risk of contamination.

⑤Easy Use and Maintenance

Ease of Use

Food washing equipment should be user-friendly and easy to operate. You can judge the quality of the machine from some little details. For example, the first machine has robust casters and anchor screws for easy movement and installation, while the second one is difficult to move without casters.

Ease of Maintenance

Easy maintenance is crucial for food washing equipment. Regular maintenance ensures that the machine operates at maximum efficiency and reduces the risk of breakdowns during use. The first machine features chain covers fixed with brackets and fasteners, which is easy to dismantle, clean and replace. Chain covers of the second machine are fixed with rivets, which is way more complicated to maintain, leading to increased maintenance costs and downtime. Only professionals with professional tools can dismantle these covers.

⑥Opt for Customization

Equipment adaptability to your specific requirements is often overlooked. Does the equipment offer changeable functions and attachments, or is it only available in fixed sizes? Choose flexible and modular equipment that can be updated and modified quickly and cheaply to suit your evolving business model.

⑦Guarantee and Customer Support

It’s important to consider guarantee and customer support when choosing food washing equipment. Quality customer support ensures that any issues with the machine can be resolved quickly and efficiently, minimizing downtime and increasing productivity.

It’s advisable to choose a supplier or manufacturer that provides reliable customer support, such as technical assistance and spare parts.

In terms of consideration⑥ and ⑦, it is not merely about the quality of the machine, but the strength of the manufacture. Only qualified and true manufactures have the ability to customize machines according to specific requirements like dimension, capacity, shape, color and provide full service.

⑧Price

You get what you pay for. Certain pieces may be more expensive than others due to their features, components and quality.

If you do have a restricted budget, it’s recommended to opt for a piece that can perform the required task effectively, rather than purchasing several inferior products for a higher cost.

Conclusion

To sum up, choosing high-quality food washing equipment requires careful consideration of several factors, including quality and durability, washing performance, water consumption, impurity discharge and management, ease of use and maintenance, guarantee and customer support, strength of the manufacturer and so on. By considering these factors, you can identify a machine that meets your specific needs and requirements, ensuring that your food washing operations are efficient, effective, and safe.

If you’d like to know more about vegetable fruit washing machines manufacturers, please click to read: Top 8 Food Washing Equipment Manufacturers Worldwide.

7 回复