Introduction

Meat blenders play a vital role in meat processing. These machines are designed to mix meat with seasonings, additives, or other ingredients, ensuring uniform texture and taste while meeting the demands of high-volume production. From sausages and meatballs to ready-to-eat meals, meat blenders are indispensable in both small and large-scale operations.

Today, several global manufacturers are known for their expertise in producing reliable and innovative meat blender machines. Factories like Taibo Food Machine (China), Mepaco (USA), Iozzelli (Italy), and FATOSA (Spain) have built strong reputations in the industry.

In this article, we will explore these leading manufacturers, their history, product lines, and the unique features of their industrial meat blenders.

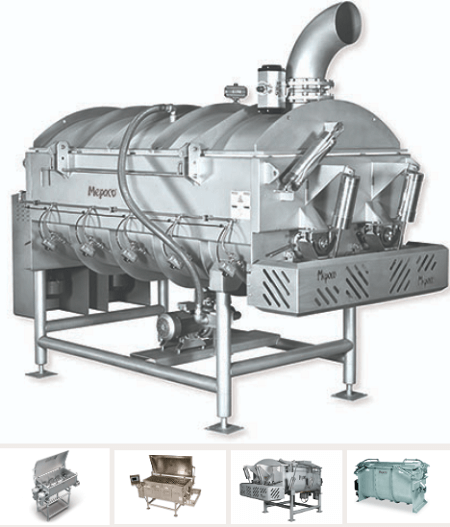

1. Mepaco

Location: 200 W. Industrial Drive, Beaver Dam, WI 53916 USA

Company Type: Manufacturer

Year Founded: 1932

Main Products:

●Mixer blender, mixer grinder, vacuum stuffer, dumpers, feeding screw conveyors, grinder integration, pump feeder.

About the Company:

Mepaco, originally known as the Meat Packers Equipment Company, is a leading U.S.-based manufacturer of specialized food processing equipment.

Mepaco builds highly engineered systems for cooking, blending, grinding, pumping, stuffing, dumping, conveying, and material handling, tailored to meet customers’ safety, sanitation, production, and maintenance objectives. The company offers a broad equipment lineup, including mixer-blenders, mixer-grinders, cookers, pump feeders, vacuum stuffers, screw conveyors, lift and dumper solutions, and more.

From its roots in meat processing to its modern innovations, the company remains focused on delivering robust, sanitary, and highly adaptable equipment—backed by comprehensive engineering and service support.

About the Mepaco Industrial Mixer Blender Series:

The mixer blender series is engineered for versatility, performance, and reliability in demanding industrial applications. Built with heavy-duty 304 or 316 stainless steel, these machines ensure compliance with the highest food safety standards. With capacities ranging from 50 to 15,000 pounds, the meat blender series offers scalable solutions for both small-batch and large-scale production.

Designed to deliver quick, accurate, and homogeneous blends, these industrial mixer blenders help processors reduce cycle times and maximize productivity goals. A wide range of customization options—including paddle, overlapping paddle, ribbon, or solid flight agitation systems, and multiple discharge configurations allows every unit to be tailored to meet specific processing requirements.

With their robust construction, customizable options, and advanced thermal control systems, these mixer blenders provide food processors with a proven solution for reliable blending, temperature management, and process flexibility.

2. Taibo Food Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Beet slicer machine, meat processing equipment, meat cutting equipment, industrial vegetable washer, vortex fruit washer, bowl cutters, frozen meat block flakers, industrial vacuum tumbler, industrial dicer machine.

About the Company:

Taibo Food Machine is a leading Chinese manufacturer of food processing equipment specializing in a broad range of machinery and turnkey production lines.

Taibo provides comprehensive solutions that include standalone machines as well as fully integrated processing lines. Their equipment spans washing, peeling, cutting, drying, dehydrating, sorting, grading, and a variety of meat, bakery, nut, and potato snacks processing systems.

Built on a foundation of 10+ years of industry expertise, ODM & OEM capabilities, and a robust in-house team for design, manufacturing, and after-sales support, Taibo continues to uphold its commitment to quality, innovation, and customer satisfaction.

About the Taibo Meat Mixer Blender:

This 2-shaft mixer blender for meat stuffings and fillings is engineered to deliver exceptional performance in meat processing, particularly for products like sausages, hamburger patties, and meatballs. It ensures uniform blending of various meat cuts, spices, and additives, resulting in consistent quality and optimal flavor distribution.

(Click to know more)

Constructed from 304 stainless steel, the machine meets international food health standards, ensuring durability and ease of cleaning. The dual-shaft design enables four mixing directions, enhancing the mixing efficiency and uniformity of the product.

This mixer is suitable for a range of applications, including the preparation of meat snacks, and is designed to meet the demands of modern meat processing facilities seeking high-quality, efficient, and hygienic mixing solutions.

3. Iozzelli

Location: Via Pablo Neruda 27 – 51100 Pistoia, Toscana – Italia

Company Type: Manufacturer

Year Founded: 1945

Main Products:

●Grinders, cutters, mixers, blenders, stuffers, frozen food processing machines, special machines.

About the Company:

Iozzelli is an established manufacturer of food processing machinery, recognized for its commitment to delivering strong, reliable, and innovative technology to the food industry. From its beginnings, the company has dedicated itself to designing equipment that meets the diverse needs of processors with efficiency, durability, and precision.

Backed by decades of solid know-how and long-lasting tradition, Iozzelli continues to serve a wide spectrum of industries, including meat, vegetables, filled pasta, fish, cheese, dairy, pet food, and fine food.

Driven by ongoing research and development, Iozzelli develops updated, efficient, and dependable solutions that keep pace with the evolving requirements of modern food processing. Combining tradition with innovation, Iozzelli remains a trusted partner for companies seeking advanced machinery designed for long-term performance and reliability.

About the Iozzelli Blender:

The blender is a fully stainless-steel mixing solution designed for versatility, durability, and hygienic performance in food processing. Built with front-end discharge functionality and equipped with non-interlocking paddle or spiral-ribbon shafts, the machine ensures efficient and uniform mixing for a wide variety of products, including ground meat, emulsions, sauces, and salads.

With mixing tank capacities ranging from 400 to 5,000 liters, the blender meets the production needs of both small and large-scale processors. Its front-end discharge system allows seamless transfer of mixed products into hoppers, where they can be further conveyed via screw, conveyor belt, or pump, streamlining the processing line.

Robust, adaptable, and easy to integrate, the industrial blender machine offers a reliable solution for modern food processors seeking high performance and sanitation standards across diverse applications.

4. FATOSA

Location: Ctra. de Terrassa, 217, 08205 Sabadell (Barcelona), SPAIN

Company Type: Manufacturer

Year Founded: 1969

Main Products:

●Mincers, mixers, cutters, frozen block cutters, lifters.

About the Company:

FATOSA is a trusted manufacturer of food processing machinery, known for its quality, innovation, and adaptability. The company’s very first machines were designed for small-scale factories and export, and over the decades FATOSA has grown into a global supplier with a product line that now includes more than thirty models.

All FATOSA machines are designed by its in-house engineering department, which continuously incorporates the latest technological developments, market needs, and international health and safety directives into every design. This commitment to innovation ensures equipment that is accurate, robust, and long-lasting, meeting the demands of both small and large-scale food processing operations.

With a legacy of continuous development in design, quality, and safety, FATOSA remains a global partner to the food industry, providing machinery built on tradition, innovation, and customer-focused solutions.

About the Fatosa Mixer Series:

This mixer series is a highly versatile solution designed for a wide variety of food products, including vegetables, meat, and fish. Its two Z-shaped arms, which can rotate in both directions, ensure fast and efficient mixing. This design delivers excellent kneading and blending results, giving the final product a superior appearance and texture.

Safety is a key focus of these meat blending machines. Each machine is equipped with an emergency stop, a safety mechanism on the bowl cover, and a two-handed unloading control to protect operators during use. The motors are protected against overheating and overloading, while the press-button controls operate at a safe 24 V and carry an IP66 protection rating, ensuring reliability even in demanding environments.

With their robust construction, versatile configurations, and advanced safety and hygiene features, the blender mixer series is an ideal choice for food processors seeking reliable and efficient mixing technology

Conclusion

Meat blenders are the backbone of many food production facilities, helping processors achieve consistent product quality while saving time and labor. Whether you are a small processor seeking a reliable mixer or a large facility requiring advanced, high-capacity solutions, these manufacturers provide proven options to meet diverse production requirements.

If you are considering upgrading or expanding your production line, explore the solutions offered by these trusted meat blender manufacturers today.

More to Read

●Batch Frying Machinery: Efficient Solution for Industrial Food Processing

●Top 4 Industrial Meat Stuffing Mixer Manufacturers Worldwide

●The Ultimate Guide to Choose the Right Industrial Meat Stuffing Mixer

一个回复