When it comes to sourcing high-quality industrial vegetable washers, Australia boasts a vibrant market with several renowned manufacturers. In this article, we will explore the best 6 vegetable washer manufacturers in Australia, providing an overview of their expertise, product offerings, and commitment to quality.

1. edp

Location: 33 – 37 O’Brien Street, PO Box 251, Mooroopna VIC 3629, Australia

Company Type: Manufacturer

Year Founded: 1947

Main Products:

●Pre-pack bagging equipment, crate filler, citrus tray filler, poly bagging equipment, met bagging equipment, net clipping machine, combination weighing equipment, citrus weigher, palletizing equipment, bin tipper, bin filling equipment, mechanical sizing equipment, bulk hopper equipment, flat bed vegetable washer, washing potato grading line.

About the Company:

edp, a prominent Australian company, has established itself as a leading supplier of comprehensive fresh fruit and vegetable grading and packaging solutions. With a rich history spanning over seventy years, edp brings a wealth of knowledge and experience to its customers.

edp has operated as an original equipment manufacturer, providing packaging machinery and solutions for fresh produce to both the Australian and export markets. Over the years, the company has expanded its offerings by fostering strong partnerships with European manufacturers.

The company understands the unique requirements of the fresh produce sector and has continuously evolved to meet the changing needs of the market. Whether it’s processing, grading, packaging, or handling, edp offers a comprehensive range of machinery and consumables to ensure the efficient processing and packaging of fruits and vegetables.

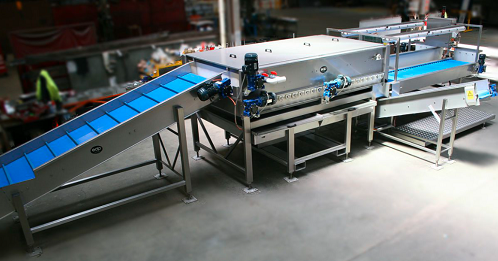

About the edp Vegetable Washer:

edp has flat bed vegetable washer and washing grading line for potatoes, citrus and root vegetables.

This flatbed washer is a versatile and durable solution for produce washing. Available in various sizes, it features 38 rows of brushes by 1800mm wide, with a capacity of over 50 tonnes per hour. The washer includes a variable speed draper chain for consistent product flow and three high-pressure spray heads for different water supplies. Built entirely in stainless steel, it offers longevity and reliability.

Optional features include variable speed drivers, a draper chain, collection tray, and pressure pump. solution for produce washing.

2. Taibo Machine

Location: Zhujie Factory Area, Zhucheng City, Shandong Province, China

Company Type: Manufacturer

Year Founded: 2013

Main Products:

●Food processing equipment, food processing line for fruit, food washing equipment, industrial vegetable processing equipment, dough rounder machine, dough processing equipment, meat processing machine.

About the Company:

While our focus is on the Australian market, it is crucial to acknowledge the global presence and influence of top manufacturers in the industry. One such standout company is Taibo Machine, a leading manufacturer based in China.

As a factory-driven company, the company takes pride in their expertise in design, development, and customization. their dedicated team of professionals is committed to delivering innovative solutions that meet the unique requirements of our valued customers. Whether you need standard equipment or customized solutions, Taibo Machine is here to fulfill your specific needs.

Although not an Australian-based company, the inclusion of Taibo Machine in this list reflects the company’s global recognition and its significant contributions to the food processing industry. With their advanced technology, innovative designs, and commitment to excellence, they have successfully established themselves as a trusted supplier in various international markets, including Australia.

About the Taibo Vegetable Washer:

Taibo produces various food processing vegetable washers including air bubble vegetable washer, leafy vegetable washer, root vegetable washer, tilting basket vegetable washer, vegetable brush washer, vortex washing machine and so on.

Some of them can be integrated with ozone generator. The o3 vegetable washer delivers thorough cleaning and disinfection.

3. TRIPAX

Location: Factory 10, 5 Edelmaier Street, Bayswater, VIC 3153, Australia

Company Type: Manufacturer

Year Founded: 1957

Main Products:

●Cheese block shredder, conveyor, bucket elevator, baton cutter, bean snipper, pumpkin cabbage segmenter, large abrasive peeler, spin dryer, fruit and vegetable washing line, rotary bug and debris removal washer, belt washer.

About the Company:

Tripax is a leading provider of equipment and solutions for the food and pet food industries. With a dedicated team based in Melbourne, Tripax offers customized solutions tailored to meet the specific needs of its clients while ensuring the highest quality in the industry.

As an expert in the Oceania market, Tripax stands out by having its own in-house engineering department, allowing for precise customization and optimization of its solutions.

At Tripax, experienced design engineers are committed to understanding your unique requirements and processes. They work closely with you to develop equipment and processes that are tailored to your individual needs. Recognizing that every processor is different, Tripax takes great care in offering the most practical and cost-effective solutions.

About the Tripax Vegetable Washer:

The Series 4001 Washline of Tripax is a highly efficient and versatile washing solution designed specifically for leafy salad products, herbs, and whole & cut vegetables. This single width and single length hybrid washer incorporates various advanced features to ensure thorough cleaning and optimal product quality.

Equipped with a submersion drum, bug removal system, and re-circulating water with a cooling coil, the Series 4001 Washline effectively removes debris, undersized particles, and floating foreign particles. It features a vortex agitation mixing system with manual valve control, allowing for precise control of water movement and back flushing.

Cleaning and maintenance are made easy with the easily removable rear water board, facilitating quick cleaning and replacement. The washline also includes a quick release drain valve for convenient cleaning and automatic water top-up with an overflow system for excess water.

4. Wyma Solutions

Location: 580 Doyles Road, PO Box 1158, Shepparton, Victoria 3630, Australia

Company Type: Manufacturer

Year Founded: 1962

Main Products:

●Bin tipper, hopper and bunkers, conveyors and elevators, destoner, debris removers, pumpkin brusher, barrel washer, flat bed washer, polisher, peeler, drying tunnel, length sizer, scree sizer.

About the Company:

Wyma Solutions is a leading company in the post-harvest sector, specializing in innovative solutions for the vegetable industry. With a strong focus on customer outcomes and quality, Wyma has established itself as an agile and trusted partner. Headquartered in Canterbury, New Zealand, and with production facilities on two continents, Wyma operates in over 50 countries. With over 50 years of experience, Wyma’s equipment is renowned for its quality and effectiveness.

The company’s philosophy of continuous improvement, teamwork, and strong customer relationships drives their commitment to delivering top-notch solutions that minimize downtime, reduce waste, and optimize produce quality.

With a deep understanding of customer needs and market demands, Wyma is dedicated to providing tailored post-harvest solutions that add value to businesses and meet the expectations of their customers.

About the Wyma Vegetable Washer:

Wyma Solution produces barrel washer, combi washer, combi system and flat bed washer.

The barrel washer is designed to gently and effectively wash fresh produce, removing soil and small stones. With a rotating perforated barrel and agitation bars, it ensures thorough cleaning. Debris is collected in hoppers underneath, and dump valves clear build-up. The outfeed elevator allows for adjustable height and gentle handling.

The combi washer integrates a barrel washer and a tank destoner and the combi system integrates a destoner, barrel washer and floating debris remover in one machine.

The flat bed washer offers a tailored solution to meet customers’ exact needs. Made up of individual modules, it provides a gentle and thorough clean for produce. Transfer mechanisms smoothly move the produce over brushes and rollers. The machine features an outfeed brush roller system, water catchment tray, and easy cleaning access. With a modular build, it offers flexibility for future modifications.

5. Tna Food Processing and Packaging Solution

Location: 24 Carter Street, Lidcombe NSW 2141, Australia

Company Type: Manufacturer

Year Founded: 1982

Main Products:

●Air cooling system, continuous frying system, belt dryer, hot washing system, speed washing system, shear washing system, water cutting system, steam peeler, abrasive peeler, drum washer, combination drum washer and destoner.

About the Company:

tna is a globally renowned company that specializes in providing integrated food processing and packaging solutions. With a remarkable presence in over 120 countries, tna has installed more than 14,000 systems worldwide. The company offers an extensive range of products, including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labeling, metal detection, verification, and end-of-line solutions. Additionally, tna provides various options for production line controls integration, SCADA reporting, project management, and training.

What sets tna apart is its unique combination of innovative technologies, extensive project management expertise, and round-the-clock global support. This ensures that customers can achieve faster, more reliable, and flexible food products at the lowest cost of ownership.

About the tna Vegetable Washer:

The first is tna ultra-cleanCOMBO 3, an innovative and highly efficient machine designed to streamline the cleaning process for root vegetables, specifically potatoes. This 3-in-1 cleaning solution effectively removes soil, stones, and other impurities from the vegetables, ensuring optimal quality and hygiene.

With its compact size and small footprint, the ultra-cleanCOMBO 3 is a perfect fit for smaller production lines. It can be seamlessly integrated ahead of your preferred peeling system, maximizing the efficiency of your overall potato processing operation.

The second is drum washer, designed to remove clay shells, sand, and soil from potatoes and other root vegetables. With its advanced technology, this machine ensures thorough cleaning without causing any damage to the produce.

One of the key advantages is its simple design, which translates to minimal maintenance requirements. This not only saves time but also helps to minimize production downtime, ensuring smooth and uninterrupted operations.

6. KW Automation

Location: P.O. Box 121, Old Bowling Green Road, Palmwoods, Queensland, Australia

Company Type: Manufacturer

Year Founded: 1970s

Main Products:

●Horticulture Nursery Equipment

●Aquaculture Equipment

●Fruit Vegetable Equipment

●Bulk bin tipper, creep feeder, brush wash or wax unit, drying tunnel, polish unit, inspection conveyor, circular weight grader, diverging belt grader, electronic weight grader, wash tank, pressure wash, ginger washer.

About the Company:

KW Automation is a leading Australian company specializing in horticultural and aquaculture automation. With a history dating back to the 1970s, the company was founded by Kurt Weisenberger and has since been driven by a passion for innovation and efficiency. Under the leadership of Michael Weisenberger, KW Automation continues to excel in providing quality and affordable automation solutions to customers in the domestic and international markets.

The company prioritizes research and development, sourcing top-quality components from around the world to ensure their products meet the highest standards. They offer on-site evaluations, modular equipment expansions, and service contracts to ensure optimal utilization of their machinery.

Committed to their mission of delivering accurate and reliable automation systems, KW Automation is dedicated to customer service and support. Their professional team is well-trained and experienced, providing assistance to the horticultural and aquaculture industries.

About the KW Vegetable Washer:

KW Automation mainly manufactures three types of produce washing machines: the vegetable brush washer, tank washer, and water jets washer. These machines are suitable for washing avocado, mango, citrus, apple, tomato, squash, pumpkin, ginger, capsicum, as well as certain aquaculture products like oyster and abalone.

The tank washer is designed to effectively remove unwanted soil through a soaking process.

The vegetable brush washer offers a variety of brush options and widths, allowing growers to customize the machine to their specific needs. The height of the washing machines is adjustable, ensuring easy accessibility to pre-existing vegetable and fruit processing lines. Additionally, some of the brush washers are equipped with wax pumps and wax spray nozzles, further enhancing the processing performance.

The ginger washer stands out with its complete stainless-steel construction. It utilizes high-pressure water jets on both the top and bottom, ensuring thorough washing and cleaning of ginger.

Conclusion

This article has provided an overview of the best 6 vegetable washer manufacturers in Australia, highlighting their expertise, product offerings, and commitment to quality. Each company brings unique strengths to the market, catering to the diverse needs of customers in the food processing industry.

From the well-established edp, with its long-standing history in manufacturing, to the innovative solutions offered by Taibo Machine in China, these manufacturers offer a range of options for sourcing top-quality vegetable washers. Tripax, Wyma Solutions, Tna Food Processing and Packaging Solution, and KW Automation also contribute to the vibrant vegetable washer market in Australia, each bringing their own specialization and expertise to the table.

If you’d like to know more about food processing and vegetable washing equipment, please click to read.

●Best 7 Manufacturers of Small Farm Vegetable Washing Equipment

●From Fresh to Dried: Exploring the Different Types of Fruit Processing Lines