Introduction

In today’s fast-paced food processing industry, precision, speed, and consistency are essential. Whether you’re producing pre-packaged vegetables, frozen meals, or ready-to-cook mixes, cutting carrots manually is no longer practical. That’s where an industrial carrot cutter machine comes in—saving time, reducing labor, and ensuring perfect, uniform cuts every time.

At Taibo Machine, we specialize in manufacturing reliable and high-efficiency carrot and beetroot cutter machines designed for commercial and industrial use.

Ⅰ. What Are Carrot Cutter Machines?

Carrot cutter machines are industrial food processing machines designed to cut carrots into specific shapes such as slices, sticks, or cubes. These machines are commonly used in large-scale vegetable processing lines, central kitchens, catering operations, and frozen food factories to increase productivity and ensure uniform cutting.

(Click to Know More)

At Taibo Machine, we manufacture a variety of electric carrot cutter machines tailored to different production needs. Whether you need thin slices for drying, uniform sticks for stir-fry mixes, or precise cubes for ready meals, we offer specialized equipment for each purpose.

Our machines are built to handle high volumes efficiently, while delivering clean, accurate cuts that reduce waste and save labor.

Ⅱ. Types of Carrot Cutting Machines

At Taibo Machine, we provide a selection of specialized carrot cutting machines designed to meet various processing needs. Each machine is crafted with precision, ensuring efficiency, durability, and ease of use. Below is an overview of our featured models:

1. Carrot Slicing Machine

The carrot slicing machine is engineered for high-efficiency slicing of root vegetables, including carrots, beetroots and more. This versatile machine can produce uniform slices, threads, and rings, making it ideal for diverse processing requirements.

The machine features two interchangeable lids, enhancing its adaptability to different cutting tasks. Its robust design allows for continuous operation, significantly boosting productivity in industrial settings.

(Click to Know More)

Key Features:

●Versatile Cutting Options: Capable of producing slices, threads, and rings to suit various culinary applications.

●High Efficiency: Designed for large-scale operations, delivering consistent and precise cuts.

●Durable Construction: Made entirely of SUS304 stainless steel for longevity and hygiene.

●User-Friendly Design: Equipped with interchangeable lids for easy customization and operation.

Parameters:

●Slice thickness: 1–10mm (adjustable)

●Output capacity: 1.5-3t/h

●Applications: Chips, dried vegetables, stews, and soup mixes

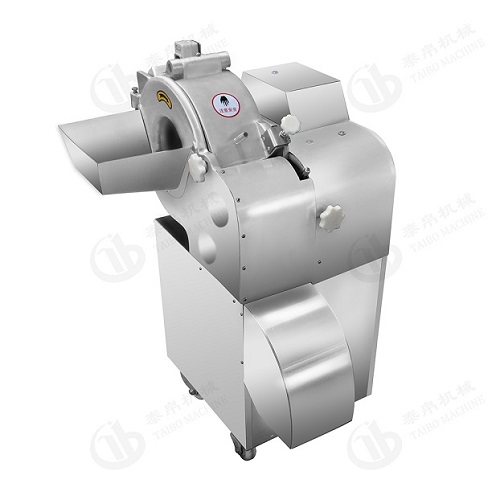

2. Carrot Cubes Sticks Cutting Machine

The carrot cubes sticks cutting machine is specifically designed for dicing vegetables and fruits into uniform cubes and cuboids. It is particularly effective for processing carrots, potatoes, cassava, beets, onions, and pickles.

By removing one knife, the machine can also be used as carrot stick and strip cutter machine, cutting carrots into uniform sticks (julienne style), perfect for French fries, salads, or stir-fry ingredients.

Constructed with aluminum-magnesium alloy and stainless steel, the carrot dicing machine offers corrosion resistance and durability. It can operate as a standalone unit or be integrated into a production line, making it suitable for various processing environments.

(Click to Know More)

Key Features:

●Precision Dicing: Delivers consistent and uniform cubes, enhancing product quality.

●Versatile Output: Capable of producing both cubes and sticks by adjusting the blade configuration.

●Flexible Integration: Operates effectively as a standalone machine or within an integrated production line.

Parameters:

●Dice size options: 4mm, 6mm, 8mm, 10mm, 12mm, 15mm (customizable)

●Output capacity: 1000kg/h

●Applications: Fast food chains, frozen vegetable lines

3. Multifunctional Carrot Cutting Machine

This carrot cutter machine offers multifunctional capabilities, making it suitable for cutting both stem and leaf vegetables, as well as root vegetables like carrots. It can efficiently produce sections, shreds, slices, threads, and cubes, providing flexibility for various processing needs.

The machine’s adjustable cutting sizes and intuitive control panel allow for precise customization, ensuring optimal results for different vegetable types. Its dual-head design enhances productivity by enabling simultaneous processing of multiple vegetables.

(Click to Know More)

Key Features:

●Multifunctional Cutting: Handles a wide range of vegetables, delivering various cut styles including sections, shreds, slices, threads, and cubes.

●Adjustable Cutting Sizes: Easily customizable settings to achieve the desired cut dimensions.

●Dual-Head Design: Allows for simultaneous processing, increasing efficiency and throughput.

●Intuitive Controls: User-friendly interface for straightforward operation and adjustments.

Parameter:

●Output capacity: 1000kg/h

4. Carrot Shredding Machine

This carrot shredding machine is tailored for julienne-style cutting, ideal for creating uniform shreds of carrots and similar vegetables like cucumbers, burdock, and cassava.

This machine is perfect for applications requiring fine, consistent shreds, such as salads, garnishes, and stir-fry dishes. Its specialized design ensures minimal waste and maximum yield, contributing to cost-effective operations. The machine’s compact footprint allows for easy integration into existing processing lines without requiring extensive space.

(Click to Know More)

Key Features:

●Specialized Shredding: Produces fine, uniform julienne cuts suitable for various culinary uses.

●High Yield Efficiency: Designed to minimize waste and maximize product output.

●Compact Design: Easily fits into existing processing setups, optimizing space utilization.

●Easy Maintenance: Simplified components for straightforward cleaning and upkeep.

Parameters:

●Cutting size: Width: 1-10 mm, Thickness: 1-10 mm, Length: 20-200mm

●Output capacity: 1000kg/h

5. Carrot Chopping Machine

The carrot chopping machine is a high-speed, precision cutting machine ideal for chopping carrots into fine granules or pastes. Though commonly used in meat processing, this versatile machine also excels in chopping hard vegetables like carrots, beetroots, and radishes.

It operates by rotating a bowl at high speed while sharp blades spin rapidly to chop the product with uniform texture. This makes the carrot chopper an excellent choice for producing carrot mash, purees, fillings, or baby food.

Key Features:

●Fine Chopping & Mincing: Ideal for producing carrot paste, fillings, and purees with a smooth, uniform texture.

●High-Speed Operation: Rotating bowl and blades work together to ensure consistent chopping results.

●Multi-Ingredient Capable: Can also process fruits, nuts, and other vegetables alongside carrots.

Parameters:

●Capacity: Available in various bowl sizes, such as 20L, 40L, and 80L, depending on your production scale

●Cutting Speed: Up to 3,000 rpm (varies by model)

●Power Supply: Customizable for different voltages and frequencies

Ⅲ. Applications of Industrial Carrot Cutter Machines

Our machines are widely used in the following industries:

●Frozen vegetable processing

●Central kitchens and canteens

●Hospital and school meal prep

●Pre-packaged meal production

●Pickle and salad processing

Ⅳ. Why Choose Taibo Machine for Your Carrot Cutting Needs?

With years of experience in the food processing equipment industry, Taibo Machine delivers solutions that are both dependable and tailored to your production goals. Our machines are shipped to clients around the world, backed by responsive technical support and after-sales service.

What sets us apart:

●Exported to multiple countries with satisfied clients

●Customizable machines based on cutting requirements

●Competitive pricing and fast delivery

●Reliable customer service and technical guidance

Ⅴ. How to Choose the Right Carrot Cutter Machine

Choosing the right machine depends on your specific needs:

●What shape of cut do you need? (slices, sticks, cubes)

●How much do you process per hour or per day?

●Do you need multi-functionality for other vegetables?

●What are your space and power supply limitations?

If you’re unsure, our team can help you assess your requirements and recommend the best model for your production line.

Conclusion

Investing in a high-quality carrot cutter machine can significantly streamline your vegetable processing operations. With customizable designs, food-grade materials, and efficient cutting performance, our machines help reduce labor costs, improve product consistency, and boost output.

Contact Taibo Machine today to request a quote or learn more about our carrot cutting solutions.

FAQ – Carrot Cutter Machines

Q: Can your machines cut other vegetables too?

A: Yes! Our carrot cutters are also suitable for potatoes, cucumbers, onions, and similar hard vegetables.

Q: Is the cutting size adjustable?

A: Yes, each machine allows for customizable cutting sizes depending on the model and blade configuration.

Q: What’s the power supply requirement?

A: Most machines operate on 220V or 380V. We can customize based on your local electrical standards.

Q: Do you offer international shipping and support?

A: Absolutely. We’ve shipped machines worldwide and provide full technical support before and after delivery.

More to Read

●Top 8 Food Washing Equipment Manufacturers Worldwide

●8 Factors Help You Choose Quality Food Washing Equipment

●The Essential Guide to Cutting Machines for Food: Efficiency and Precision

●Efficient Beetroot Processing: Master Food Manufacturing with Beetroot Cutting Machine

一个回复